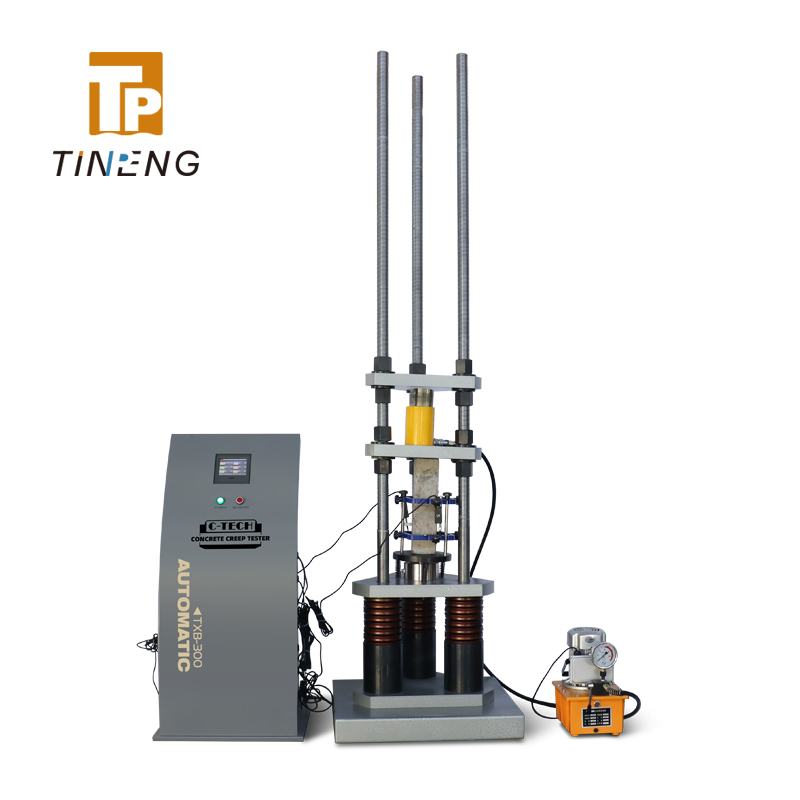

TXB-500/1000

The automatic concrete creep tester is designed to determine of concrete cylinder and cuboid parts under constant pressure load over time, ie, the creep deformation of concrete. It is applicable for concrete creep deformation test under single-direction pressure at constant temperature in a humid-free environment.

STANDARD

- ASTM C512

Get Wholesale Price

The automatic concrete creep tester is designed to determine of concrete cylinder and cuboid parts under constant pressure load over time, ie, the creep deformation of concrete. It is applicable for concrete creep deformation test under single-direction pressure at constant temperature in a humid-free environment.

Premium model

Creep frame with displacement sensors and data acquisition system

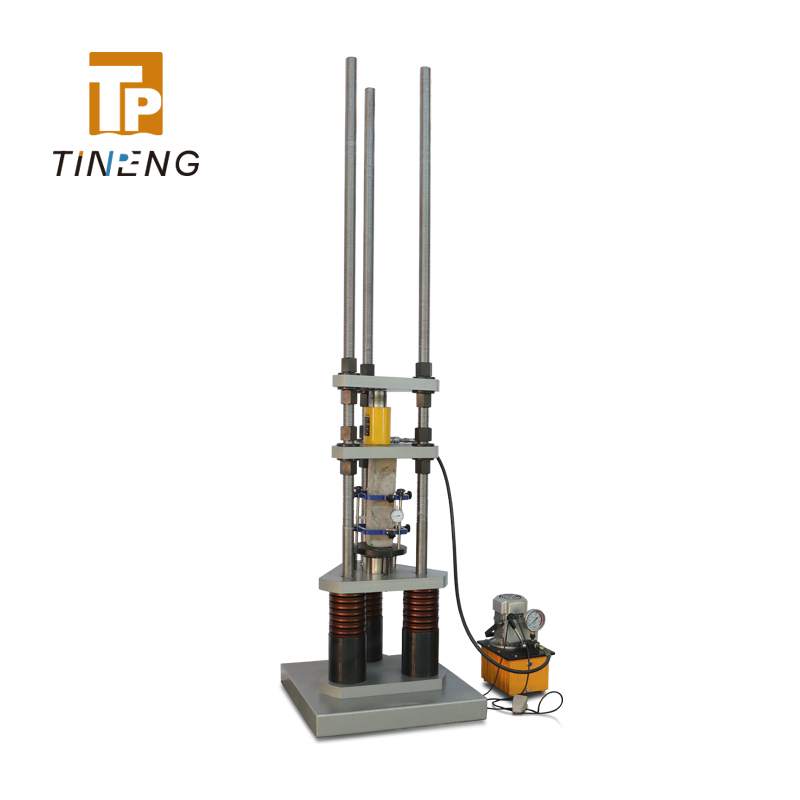

Standard model

Creep frame with dial indicators

FEATURES

◎ Adopts touch screen control system, which can display and record the pressure, compression deformation and temperature and humidity of the test environment in real time;

◎ The creep frame can be equipped with a safety cover to prevent accidental damage of the specimen and cause safety accidents;

◎ The test data is saved in real time and will not be lost due to sudden power failure, and the previous test will continue to run after power-on;

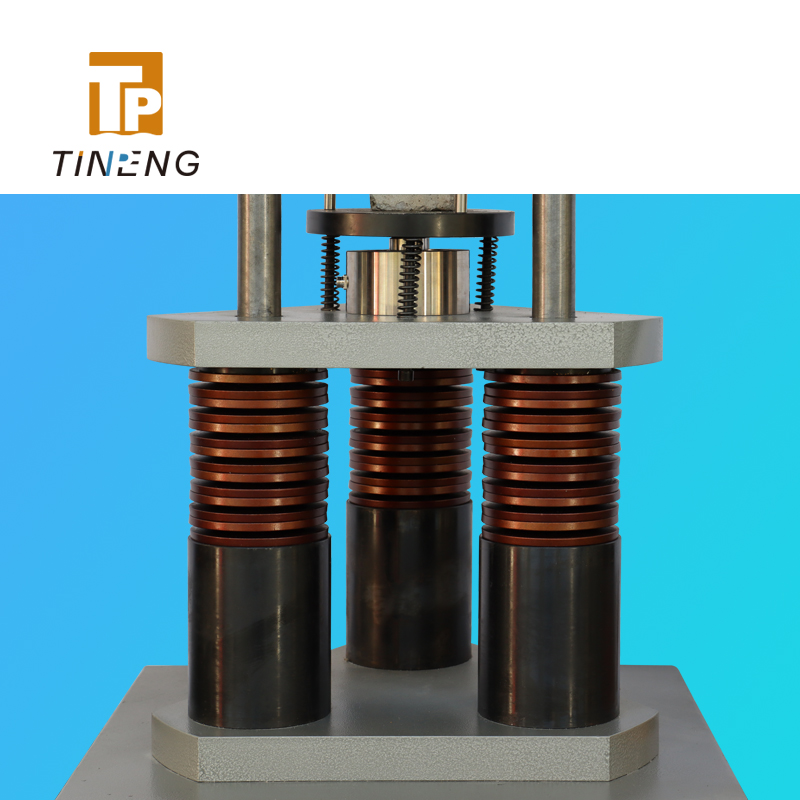

◎ Adopts disc spring and the special disc spring assembly. Anti-eccentricity, the three supports are evenly stressed, the disc spring has high strength, long fatigue life and small permanent deformation;

◎ The optimized structure design of the loading frame is convenient for users to locate the specimen and pressure device, fix the sensors, level and operate;

◎ The electric hydraulic pump station is equipped with a pressurized oil cylinder, which is convenient for pressurization and easy to control and adjust the pressure;

◎ There is a fixing device at the bottom of the loading frame, which is safe and stable during use;

◎ The bearing plate is made of high-strength steel, with high rigidity and stable performance;

◎ The equipment is transported as a whole after assembly, and can be used after the user is hoisted and fixed;

◎ The accessories are complete, the test can be carried out immediately on site.

TECHNICAL PARAMETERS

TXB-500

Max testing force: 500KN

Measurement range: 500KN

Pressure sensor: Adopts spoke-type pressure sensor, which has high anti-eccentricity, overload capacity and sensitivity.

Jack stroke: 100mm

Pressure relative error: Stroke 0~1mm linearity <0.1%

LVDT sensor: Stroke 0~1mm linearity <0.1%

Temperature sensor accuracy: ±0.5℃

Humidity sensor accuracy: ±3%

Working temperature: -20℃~+80℃

Spring height: 300mm

Specimen size: 100×100×300, 100×100×400, 100×100×515, 150×150×300, 150×150×400, 150×150×450, 150×150×600, 200×200×600mm

Creep frame dimensions: 750×750×2800mm

TXB-1000

Max testing force: 1000KN

Measurement range: 1000KN

Pressure sensor: Adopts spoke-type pressure sensor, which has high anti-eccentricity, overload capacity and sensitivity.

Jack stroke: 100mm

Pressure relative error: Stroke 0~1mm linearity <0.1%

LVDT sensor: Stroke 0~1mm linearity <0.1%

Temperature sensor accuracy: ±0.5℃

Humidity sensor accuracy: ±3%

Working temperature: -20℃~+80℃

Spring height: 300mm

Specimen size: 100×100×300, 100×100×400, 100×100×515, 150×150×300, 150×150×400, 150×150×450, 150×150×600, 200×200×600mm

Creep frame dimensions: 750×750×2800mm

TRAINING

Training services are available for this equipement, including on-site training, training videos and training documents. Contact us for a quote.

Duration: 2 days

|

|

|

| On-site training | Training videos | Training documents |