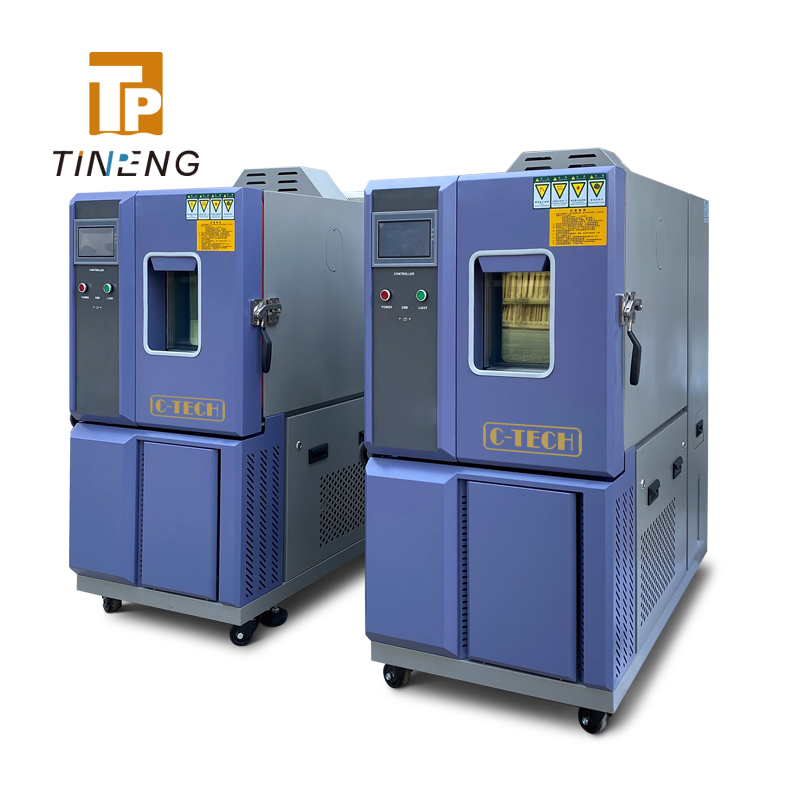

Environmental test chamber TP-TH-408DH

It is mainly used to simulate high temperature, low temperature, hot and humid environment, or high temperature, low temperature, hot and humid alternating environment that may be encountered during transportation, storage and use of electronic instruments, new materials, electrical engineering, vehicle accessories, metals, electronic products, aerospace materials, etc., to check the materials, accessories or equipment for resistance to high temperature, cold and moisture, as well as the possible damage and shortened lifespan.

STANDARD

- IEC 60068-2-2

- IEC68-2-1 TEST A

- IEC68-2-2 TEST B

- IEC68-2-3 TEST C

- MIL-STD-810D

- MIL-STD-202F

Get Wholesale Price

It is mainly used to simulate high temperature, low temperature, hot and humid environment, or high temperature, low temperature, hot and humid alternating environment that may be encountered during transportation, storage and use of electronic instruments, new materials, electrical engineering, vehicle accessories, metals, electronic products, aerospace materials, etc., to check the materials, accessories or equipment for resistance to high temperature, cold and moisture, as well as the possible damage and shortened lifespan.

TECHNICAL PARAMETERS

Temperature

Temperature control range: -40℃~+150℃

Resolution: 0.01℃

Temperature fluctuation: ±0.5 ℃

Temperature deviation: ±0.5 ℃

Temperature uniformity: ≤2.0 ℃

Heating rate: -40℃→+150℃ 4.0℃/min (no-load nonlinearity)

Cooling rate: +150℃→ -40℃ 1.0℃/min (no-load nonlinearity)

Humidity

Humidity control range: 20%-98%R.H (10%-98%R.H special conditions for selection)

Resolution: 0.1%R.H

Humidity fluctuation: ±2.0%R.H

Humidity deviation: ±3.0%R.H

Working chamber

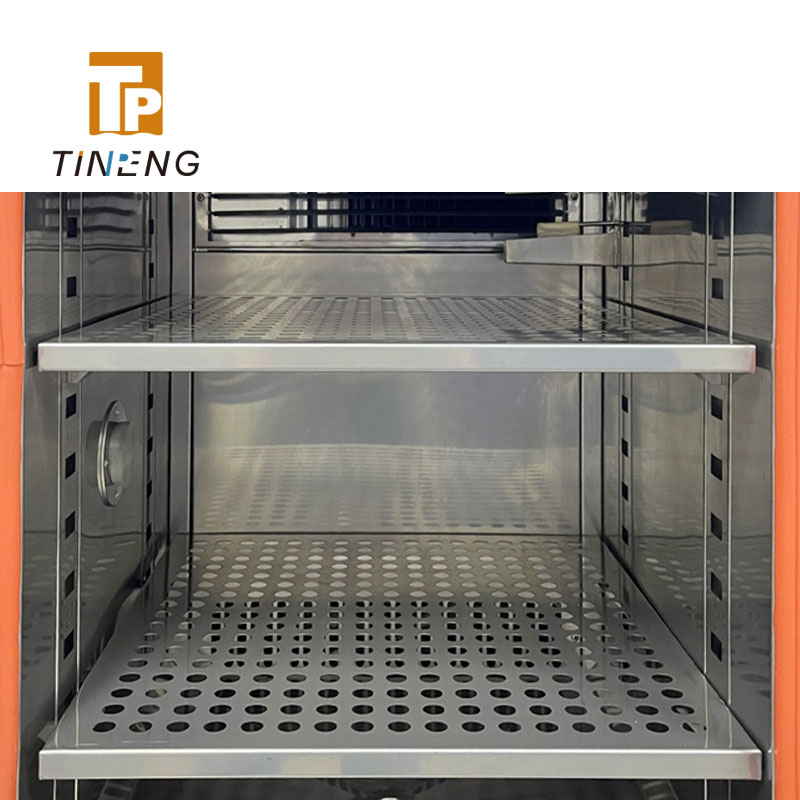

Materials: Shell: cold rolled steel sheet, ≥1.2mm; Interior: SUS304# stainless steel plate, ≥1.0mm, base plate load 50Kg; Thermal insulation material: High temperature resistant high density urethane foam insulation material

Sample rack: Equipped with two sample racks, the spacing is adjustable, and the load capacity is 20kg (50kg, 80kg, 100kg, etc. customizable)

Door: Single door, explosion-proof handle

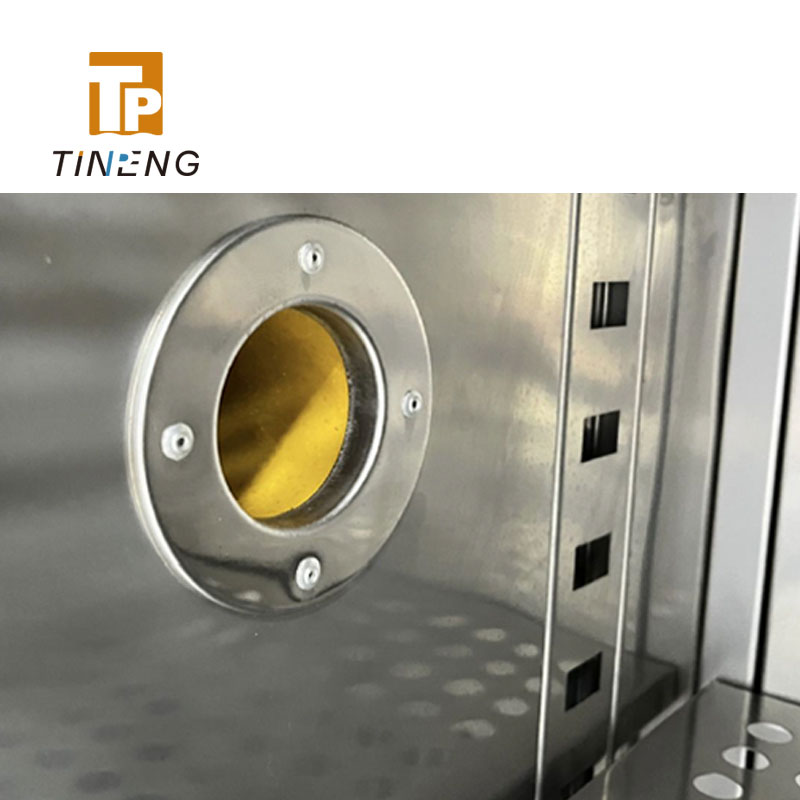

Test hole: There is a Φ50mm (customizable size) test hole on the left side of the box, with corresponding thermal insulation accessories and special sealing plugs.

Lighting: Low voltage explosion proof LED lighting, switch control.

Heating and cooling system

Heater: Electric heating, nickel-chromium alloy electric heating wire (customized)

Control mode: PID+SSR

Cooling method: A single-stage (above -40℃) or cascade (less than -40℃) cooling system is used, and heat exchange is achieved through an evaporative condenser.

Control mode: Automatic adjustment according to test conditions

Compressor: Imported ultra-low temperature compressor

Refrigerant: R404A or 232 (ozone depletion index is 0) environmentally friendly refrigerant

Condenser: Fin-type air-cooled condenser / Shell and tube water-cooled condenser

Evaporator: Laminated multi-stage evaporator

Control system

Sensor: Platinum PT-100

Controller: 7" full color touch screen

Operation mode: Customized control/program control

Temperature measurement: -90.00℃~300.00℃

Humidity measurement: 1.0%--100%R.H

Installation and working conditions

Working environment: Temperature: 20℃~35℃; Relative humidity: ≤ 85%RH; Air pressure: 86~106kpa

Power supply: 220V(±10%), 50Hz