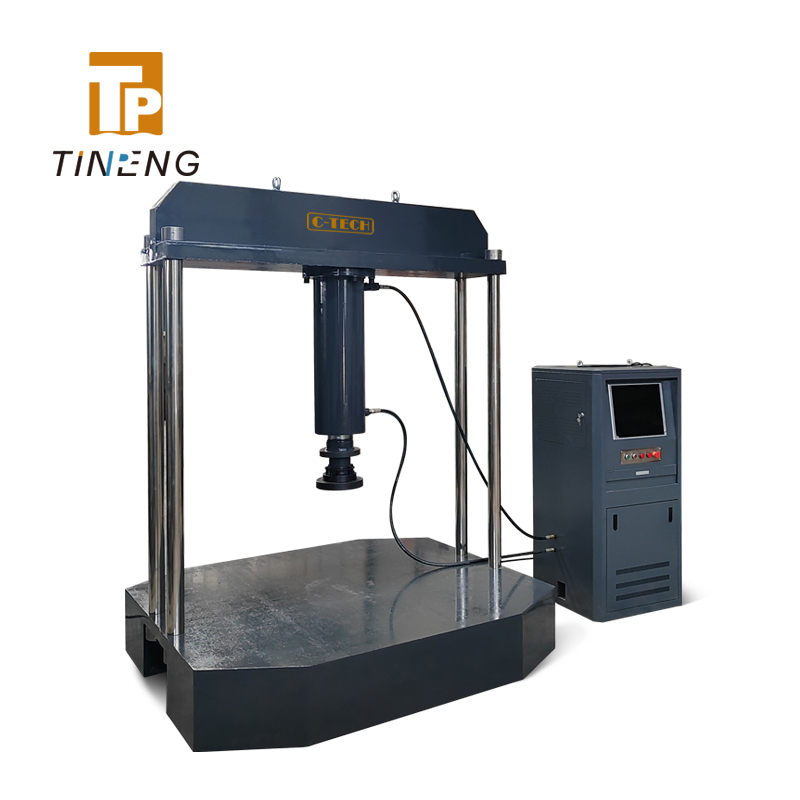

MHC-1000A

MHC-1000A electro-hydraulic servo manhole cover compression testing machine is a high-precision material testing equipment that adopts hydraulic power source drive, electro-hydraulic servo control technology, computer data acquisition and processing.

It is used to test the bearing capacity (residual deformation and test load) of manhole covers of various materials. It can realize closed-loop control such as constant-rate loading and constant-rate deformation, and can automatically obtain the technical indicators of the specimen.

MHC-1000A electro-hydraulic servo manhole cover compression testing machine is a high-precision material testing equipment that adopts hydraulic power source drive, electro-hydraulic servo control technology, computer data acquisition and processing.

It is used to test the bearing capacity (residual deformation and test load) of manhole covers of various materials. It can realize closed-loop control such as constant-rate loading and constant-rate deformation, and can automatically obtain the technical indicators of the specimen.

Features

l It adopts high sealing one-way/two-way cylinder, which is highly efficient and durable.

l The host structural parts are made of high-strength iron plates, making the whole machine rigid and stable.

l The force measuring element is a high-precision oil pressure digital sensor. The sensor has high accuracy, good repeatability and long-term stability.

l The electrical signals emitted when the force is applied are collected and processed by computer software.

l The oil source system adopts servo closed-loop control, equipped with digital servo valves, motors with stable torque and speed, high-precision valves and other components, with fast response and high sensitivity.

l The system monitors parameters such as load and deformation in real time, has features such as tracking, follow-up, and adjustability, and can achieve fully automatic and precise control.

l The measurement and control system uses a high-speed Ethernet communication interface to communicate with the computer.

l Test data is managed using a standard database and can be accessed at will. It can realize re-analysis of test data and curves, partial amplification and data re-editing. It can automatically calculate various mechanical performance indicators of materials, print out complete test reports and curves.

l Equipped with force overload protection, force channel overspeed protection, range limit protection, etc.

l The measurement and control system can be programmed by users according to test needs, such as cyclic loading, test force maintenance, etc.

TECHNICAL PARAMETERS

Max testing force: 1000KN

Accuracy class: ≥level 1

Relative error of indication value: ±1%

Effective measuring range: 1%-100%F·S (full scale not divided)

Relative error of deformation indication: ±1%

Resolution of deformation measurement: 0.001mm

Compression space: 250-300 mm

Effective distance between two columns: 1200mm

Piston stroke: 250-300 mm

Maximum speed of piston: 120 mm/min

Platen size: φ356 mm

Dimensions of the host: 1200 mm×1400 mm×1600 mm

Dimensions of the oil source cabinet: 980mm×500 mm×1100 mm

Total power Oil pump motor: 1.1KW / 1.5KW

Oil source cabinet weight: About 150 kg

Total weight About: 2500 kg