HY-UTM

HY-UTM series universal testing machine is suitable for testing various mechanical properties of asphalt mixtures and it is an important

equipment in scientific research, industrial production, quality inspection and etc.

The equipment consists of four parts: the host, the hydraulic unit, the refrigerator, and the controller. It is powered by the hydraulic unit,

and the controller controls the flow and direction of the hydraulic oil through the hydraulic valve, so that the piston rod moves according

to the predetermined pressure and position.

HY-UTM series universal testing machine is suitable for testing various mechanical properties of asphalt mixtures and it is an important

equipment in scientific research, industrial production, quality inspection and etc.

The equipment consists of four parts: the host, the hydraulic unit, the refrigerator, and the controller. It is powered by the hydraulic unit,

and the controller controls the flow and direction of the hydraulic oil through the hydraulic valve, so that the piston rod moves according

to the predetermined pressure and position.

APPLICATIONS:

- Dynamic modulus test. Perform specialized stress-strain tests under multiple temperature and frequency conditions. The equipment can automatically adjust the loading force according to the set strain range and automatically calculate test results such as dynamic modulus and phase angle.

-Fatigue tests such as flow rate, tensile fatigue, and four-point bending test. Perform cyclic loading on the specimen under constant loading force and frequency conditions until failure occurs. After the test is completed, the corresponding test results (bending stiffness, phase angle, number of failures, SC curve, etc.) are automatically displayed.

- Strength tests such as SCB, beam bending, and penetration. The test is carried out with a predetermined loading speed or a fixed loading force. When the specimen fails, the test ends automatically and the corresponding test results are automatically calculated.

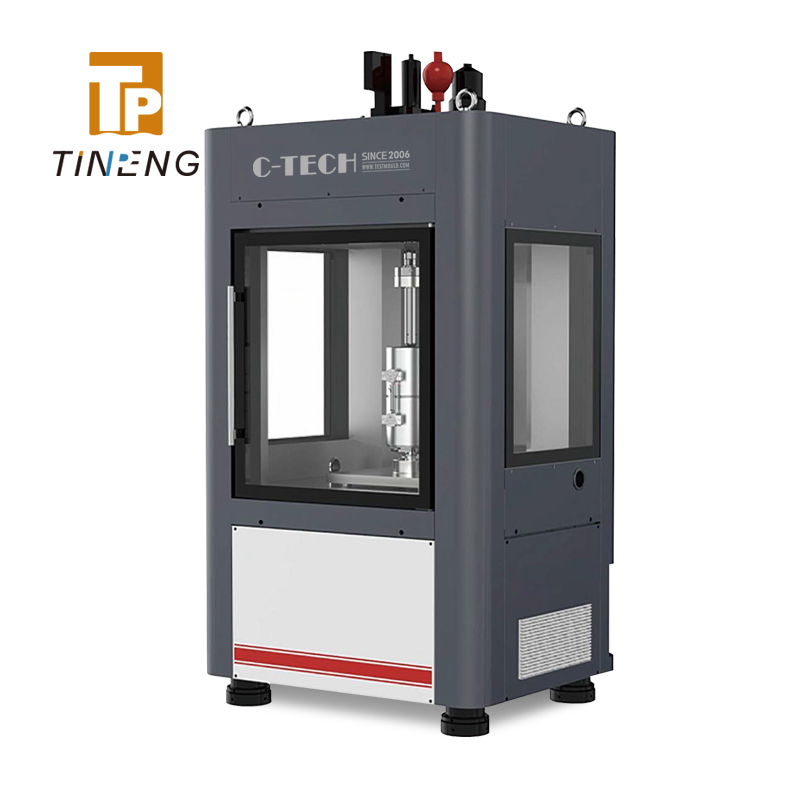

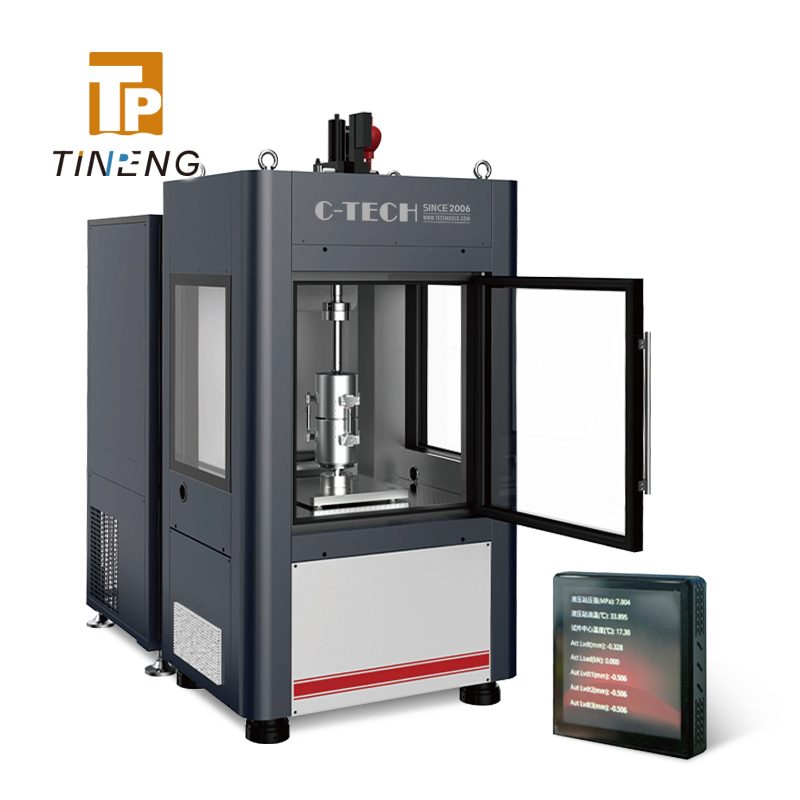

HOST:

- The four-column reaction frame structure is stable and reliable, with high parallelism, preventing load caused by misalignment during testing.

- There are viewing windows on three sides, which makes it easy to observe the condition of the internal specimens.

- The host has a small LCD screen, which makes it easy to adjust the sensor position and current value.

- Cool air circulation. Circulating air flows directly from top to bottom, ensuring high efficiency and stable, uniform flow..

- Internal dimensions: 500×840×770mm, easy to operate.

NVIRONMENTAL CHAMBER:

- The unique air duct design minimizes temperature differences to less than ±1°C. The environmental chamber adopts an advanced multi-hole directional airflow circulation system, which realizes the optimized ratio of laminar flow and turbulent flow in three-dimensional space through array-type flow guide holes and dynamic pressure balance device. This innovative design not only eliminates the temperature lag caused by traditional single-point air supply, but also dynamically compensates for heat load changes through a real-time feedback adjustment system so that the temperature difference between any two points in the environmental chamber within the temperature range of -20℃ to +80 ℃ does not exceed ±1℃.

- The thermal insulation bridge structure reduces heat conduction. The environmental chamber uses thermal insulation to isolate the internal temperature control from the external environment to ensure temperature stability.

- The glass door is equipped with a heating device to prevent the glass from fogging up when there is a large temperature difference between the inside and outside, which would affect the test observation.

TEMPERATURE CONTROL SYSTEM:

- Independent temperature control system. The system operates based on the frequency conversion control principle, thus flexibly controlling the cooling or heating power.

- It adopts color LCD touch screen control. When cooling, it accurately djusts the compressor speed and heating device power according to the difference between the temperature in the environmental chamber and the set temperature, achieving precise temperature control and high efficiency and energy saving.

- In order to prevent the vibration of the temperature control system from interfering with the test results, the temperature control system and the main unit are softly connected with flexible materials, which effectively blocks the vibration generated by the temperature control system during operation from being transmitted to the main unit, ensuring the stability of the environment in which the test sample is located during the test and the accuracy of the test data.

CONTROLLER:

- The 4-axis/13-channel control system can simultaneously control 4 actuators and collect data from 13 sensors.

- 24-bit AD conversion accuracy, combined with 8x oversampling technology, ensures high accuracy and stability of data acquisition.

- The equipment can automatically identify the fixture to avoid test failure caused by mismatch between software and fixture.

- It supports multiple control modes such as stress, strain, and load holding, and can switch automatically, suitable for dynamic or static tests.

- The dynamic control frequency is up to 70Hz, and supports custom waveform output such as sine wave, square wave, triangle wave, etc.

- All test results are automatically calculated and do not require the user to calculate them.

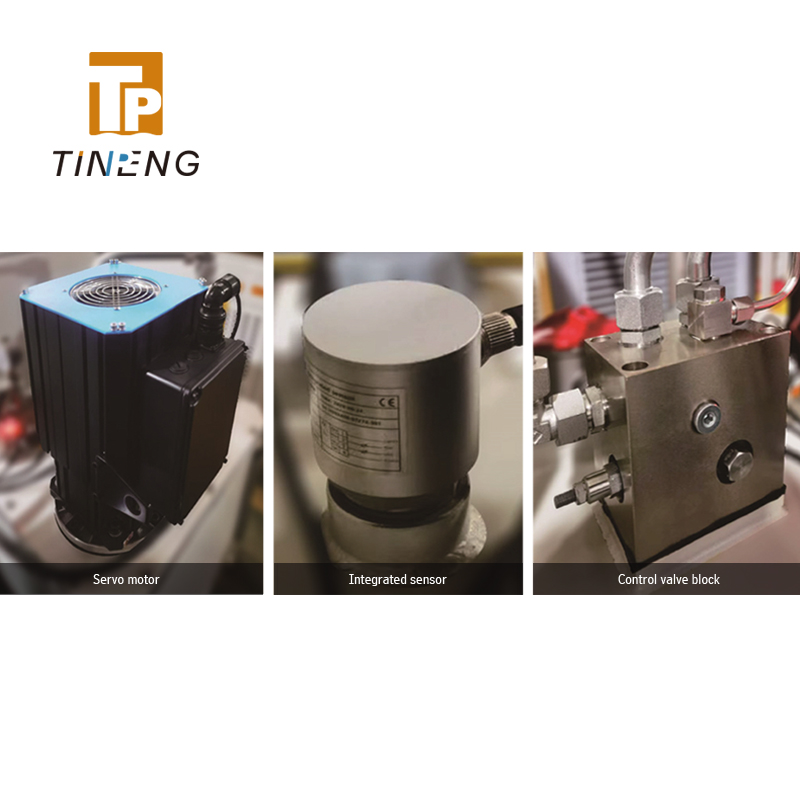

HYDRAULIC SYSTEM:

- Driven by a servo motor, it precisely controls the torque and speed of the pump to achieve accurate flow and pressure supply.

- The servo motor speed can be adjusted according to the test needs. Due to its high response frequency and torque, the hydraulic unit can quickly respond to changes in system load and effectively reduce the temperature and noise of the equipment.

- The oil tank has a heating function, which can preheat the hydraulic oil when starting in a low-temperature environment, thereby speeding up the system response and improving the test efficiency. An integrated sensor monitors the hydraulic oil temperature in real time. Combined air cooling and heating control ensures the oil temperature remains within the ideal operating range, optimizing system performance and extending equipment life.

- Through the synergistic effect of the liquid level sensor and the low liquid level alarm function, the hydraulic system has achieved an upgrade from "passive fault response" to "active health management", significantly improving operational reliability.

TECHNICAL PARAMETERS

HY-UTM-30

Actuator type: Hydraulic

Reaction frame: Four-column

Loading capacity: 30kN

Tensile force: 20kN

Force measuring method: Bidirectional force measurement at top and bottom

Load cell accuracy: 0.1%

Temperature control method: External circulating air

Environmental chamber: With viewing windows on three sides

Loading method: Stress/strain

Control method: PC

Noise level: 55~65dB

Power supply: AC380V 10A

HY-UTM-100

Actuator type: Hydraulic

Reaction frame: Four-column

Loading capacity: 100kN

Tensile force: 80kN

Force measuring method: Bidirectional force measurement at top and bottom

Load cell accuracy: 0.1%

Temperature control method: External circulating air

Environmental chamber: With viewing windows on three sides

Loading method: Stress/strain

Control method: PC

Noise level: 55~65dB

Power supply: AC380V 10A

HY-UTM-150

Actuator type: Hydraulic

Reaction frame: Four-column

Loading capacity: 150kN

Tensile force: 100kN

Force measuring method: Bidirectional force measurement at top and bottom

Load cell accuracy: 0.1%

Temperature control method: External circulating air

Environmental chamber: With viewing windows on three sides

Loading method: Stress/strain

Control method: PC

Noise level: 55~65dB

Power supply: AC380V 10A

HY-UTM-200

Actuator type: Hydraulic

Reaction frame: Four-column

Loading capacity: 200kN

Tensile force: 120kN

Force measuring method: Bidirectional force measurement at top and bottom

Load cell accuracy: 0.1%

Temperature control method: External circulating air

Environmental chamber: With viewing windows on three sides

Loading method: Stress/strain

Control method: PC

Noise level: 55~65dB

Power supply: AC380V 10A