HY-FPB30

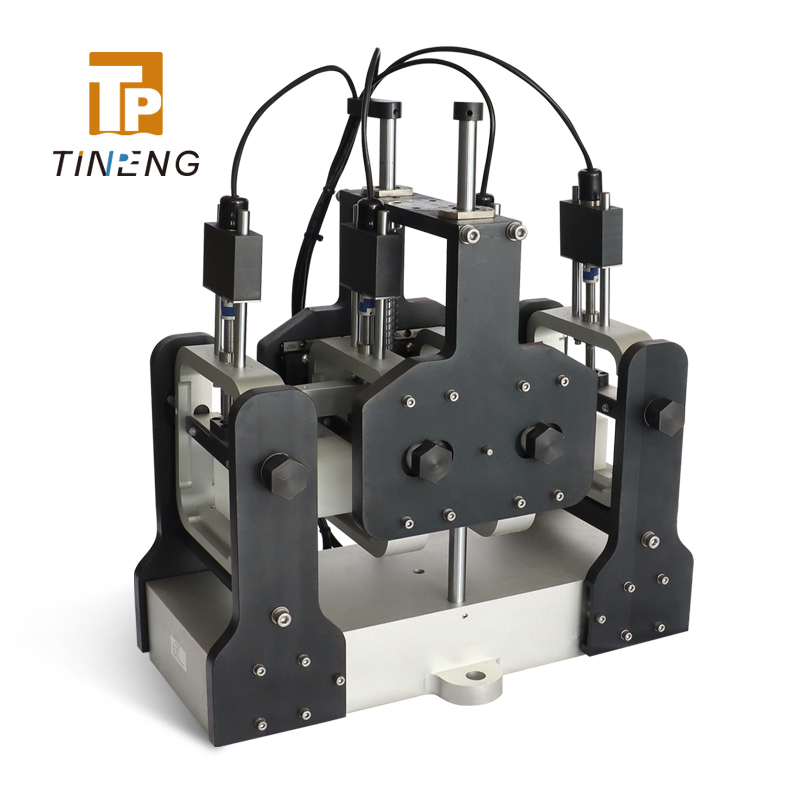

The four-point bending apparatus HY-FPB30 is a device used to evalu-ate the fatigue and flexural properties of asphalt mixtures. It is widely used in pavement material research, quality control, and mix design. The apparatus adopts hydraulic loading, which provides high loading force and easier to control loading waveform. In addition to the testing of common asphalt mixtures, it is also suitable for testing modified asphalt mixture specimens with high modulus and hardness.

The four-point bending apparatus HY-FPB30 is a device used to evalu-ate the fatigue and flexural properties of asphalt mixtures. It is widely used in pavement material research, quality control, and mix design. The apparatus adopts hydraulic loading, which provides high loading force and easier to control loading waveform. In addition to the testing of common asphalt mixtures, it is also suitable for testing modified asphalt mixture specimens with high modulus and hardness.

CONTROLLER

-Including data acquisition system and control software.

-The 4-axis/13-channel control system can simultaneously control 4 actuators and collect data from 13 sensors.

-16-bit AD conversion accuracy, combined with 8x oversampling technology, ensures high accuracy and stability of data acquisition.

-All test results are automatically calculated and do not require the user to calculate them.

-The fixture is equipped with a transponder chip, and the equipment can automatically identify the fixture to avoid test failure caused by mismatch between software and fixture.

-It supports multiple control modes such as stress, strain, and load holding, and can switch automatically, suitable for dynamic or static tests.

-The dynamic control frequency is up to 25Hz, and supports custom waveform output such as sine wave, square wave, triangle wave, etc.

SOFTWARE

-This equipment is used to measure the fatigue life of asphalt mixture under repeated bending loads under specified test conditions.

-Two loading waveforms are commonly used: partial sine and sinusoidal. It is generally believed that the moving wheel load produces stress-strain effects on the road surface that are close to a partial sine curve. There-fore, this testing method uses a par-tial sine wave as the standard loading waveform for fatigue testing.

-The termination condition is when the product of the bending modulus and the number of actions reaches the maximum, or the stiffness modulus decreases to 50% of the initial bend-ing stiffness modulus.

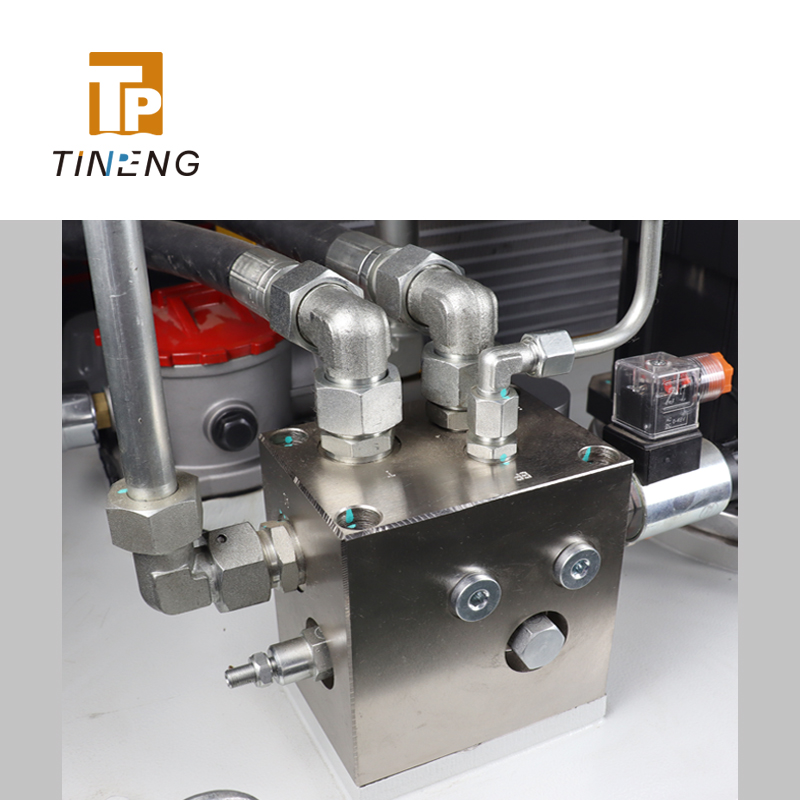

HYDRAULIC UNIT

-Driven by a servo motor, it precisely controls the torque and speed of the pump to achieve accurate flow and pressure supply.

-The servo motor speed can be adjusted according to the test needs. Due to its high response frequency and torque, the hydraulic unit can quickly respond to changes in system load.

-The software can be started remotely. The local controller has the functions of starting and switching between low and high pressure. The oil tank has a heating function, which can preheat the hydraulic oil when starting in a low-temperature environment, thereby speeding up the system response and improving the test efficiency.

-An integrated sensor monitors the hydraulic oil temperature in real time. Combined air cooling and heating control ensures the oil temperature remains within the ideal operating range of 40-60°C, optimizing system performance and extending equipment life.

-Through the synergistic effect of the liquid level sensor and the low liquid level alarm function, the hydraulic system has achieved an upgrade from "passive fault response" to "active health management", significantly improving operational reliability.

TECHNICAL SPECIFICATIONS

Actuator type:Hydraulic

Loading capacity:30kN

Tensile force:25kN

Force measuring method:Measure from the bottom:

Load cell accuracy:0.1%

Temperature control method:External circulating air

Environmental chamber:With viewing window

Loading method:Stress/strain

Control method:PC

Noise level:55~65dB

Power supply:AC380V 10A