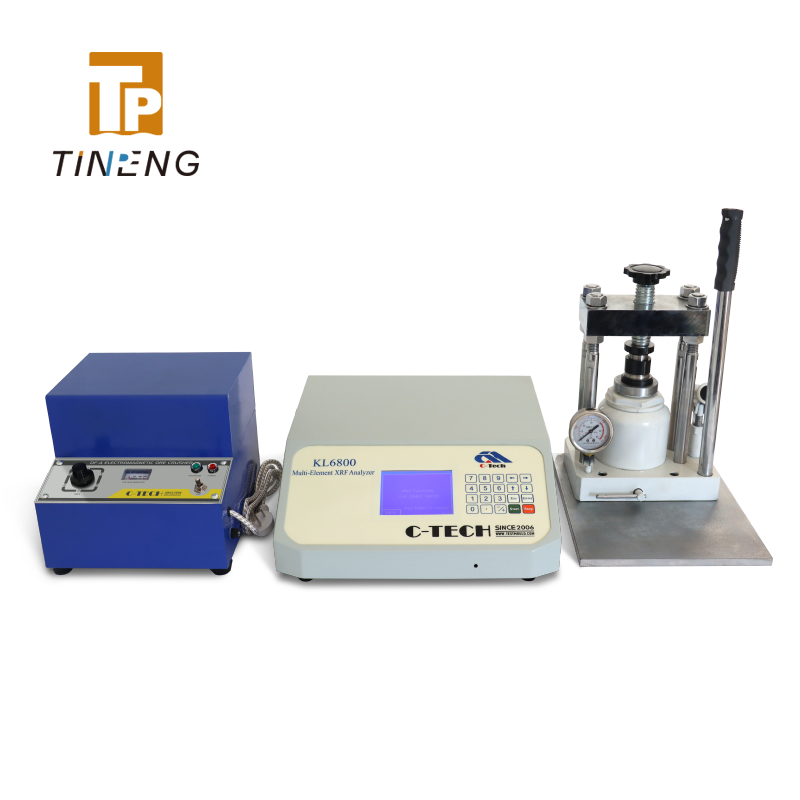

KL3300/KL6800

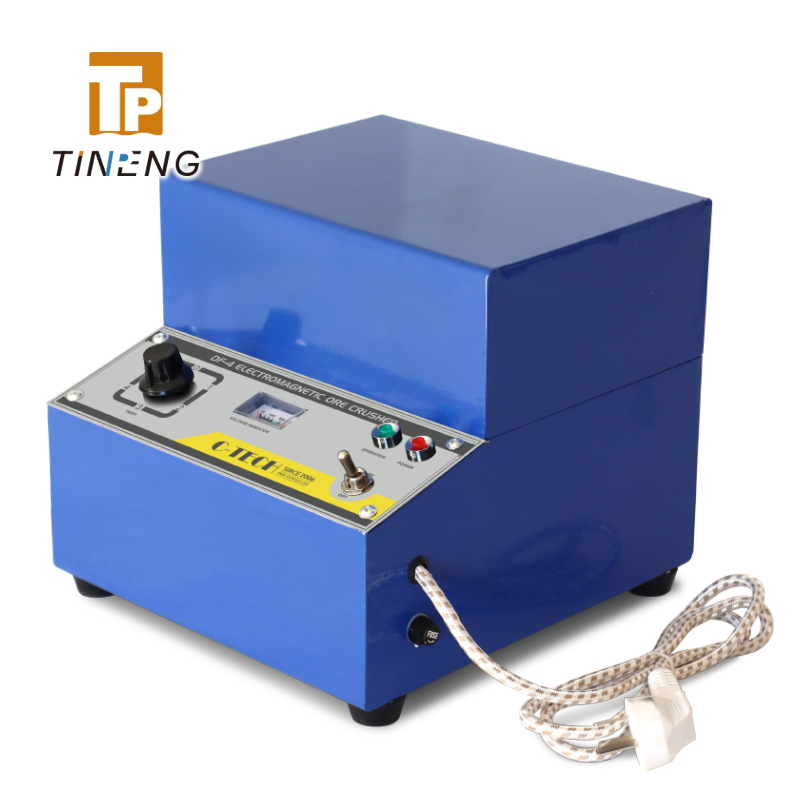

Multi-Element XRF Analyzer is a new type of computerized desktop analyzer, specially developed for the cement building materials industry. Using advanced physical measurement method, it can accurately and quickly

analyze the content of Ca, Fe, S and other elements in raw material, clinker, and cement, and automatically calculate KH, SM, IM.

The instrument can be used independently, and can also sent the analysis results to thecomputer batching system through the RS232 serial communication port.

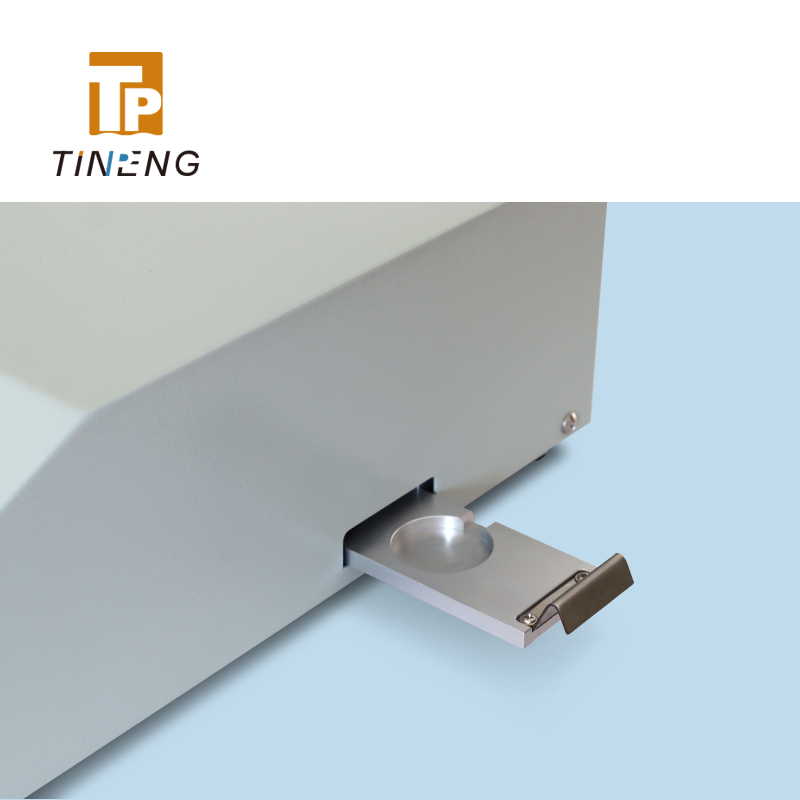

Multi-Element XRF Analyzer KL6800 is a new type of computerized desktop analyzer, specially developed for the cement building materials industry. Using advanced physical measurement method, it can accurately and quickly (180 seconds) analyze the content of CaO, Fe2O3, SiO2, Al2O3, SO3 in raw material, clinker, and cement, and automatically calculate KH, SM, IM.

The instrument can be used independently, and can also sent the analysis results to the computer batching system through the RS232 serial communication port.

APPLICATION

·KL6800 is mainly used to determine the CaO%, Fe2O3%, SiO2%, Al2O3% in raw material and clinker, and quickly provide analytical data for raw material ratio and clinker rate value.

·KL3300 is mainly used to determine the CaO%, Fe2O3% in raw material, and quickly provide analytical data for raw material ratio.

·KL6800 and KL3300 are used to determine CaO% and SO3% in cement, and to provide analytical data for admixture content.

·KL6800 is also used to analyze CaO%, Fe2O3%, SiO2%, Al2O3%, SO3% in limestone, clay, gypsum, kaolin, refractory materials and other materials, and provide quality data for incoming raw materials.

·Directly connected with the computer control system of raw material rate value batching through the RS232 serial communication port.

FEATURES

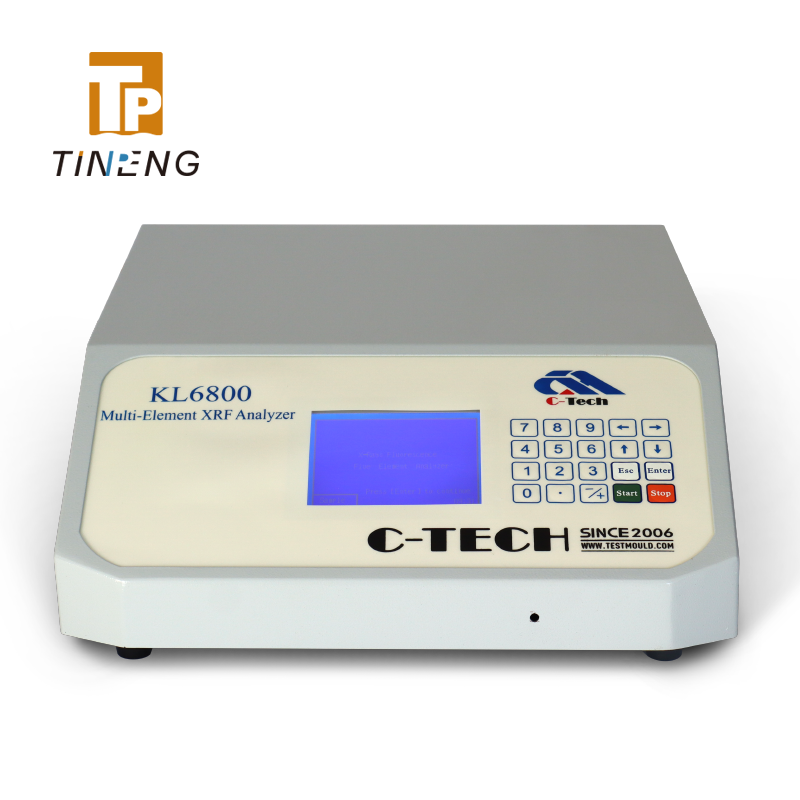

·Integrated desktop instrument, compact structure, beautiful appearance.

·Large-screen LCD display, easy to use.

·Short analysis time: determine the elements in the material in a short time.

·Samples are not destroyed during analysis, and samples can be tested repeatedly.

·No chemical reagents, no three wastes, no radioactive sources, low power consumption, in line with environmental protection,energy saving, radiation safety requirements.

·The data storage space is large, and the content results and instrument self-test data can be queried.

·Strong adaptability to the environment and high reliability.

TECHNICAL PARAMETERS

Model KL3300

Analysis range: CaO, Fe2O3, SO3: 0.01%~100%

Analysis width:SO3(CaO, Fe2O3)%max~SO3(CaO,Fe2O3)min≤15%, select the working range by calibrating the working curve.

Analysis accuracy:Standard deviation SSO3≤ 0.04%;SCaO≤0.10%; SFe2O3≤ 0.05%;

Allowable error: ΔCaO %≤0.25; ΔFe2O3%≤0.15%; ΔSO3%≤0.15%

Analysis time:n * 30 seconds (n is a natural numberfrom 1 to 5, usually n = 2)

Stability:Absolute drift: |ΔCaO%|≤0.10%; |ΔFe2O3%|≤0.10%; |ΔSO3%|≤0.10%

Working condition: Power supply: AC200V~240V, 50Hz; ambient temperature: 5~40℃; relative humidity: ≤85%(30℃)

Overall power consumption: ≤30W

Dimensions and weight: 468mm * 368mm * 136mm, 13.8Kg

Model KL6800

Analysis range: CaO, Fe2O3, SiO2, Al2O3, SO3 : 0.01%~100%

Analysis width:CaO, Fe2O3, SiO2, Al2O3, SO3 : ≤5%, for example, in rawmaterial, CaO%: 39.50%~44.50%, Fe2O3%: 0.01%~5.00%,SiO2%: 10.00%~15.00%, Al2O3%:.00%~5.00%, selected bycalibration working curve.

Analysis accuracy:

Standard deviation SCaO≤0.10%; SFe2O3≤ 0.05%;SSiO2≤0.07%; SAl2O3≤0.07%; SSO3≤0.05%

Allowable error:ΔCaO %≤0.25; ΔFe2O3%≤0.10%; ΔSiO2%≤0.20%; ΔAl2O3%≤0.20%; ΔSO3%≤0.15%

Analysis time:n * 90 seconds (n is a natural number from 1 to 5, usually n = 2)

Stability:Absolute drift:Absolute drift: |ΔCaO%|≤0.15%; |ΔFe2O3%|≤0.10%; |ΔSiO2%|≤0.10%; |ΔAl2O3% |≤0.10%; |ΔSO3%|≤0.10%

Working condition:Power supply: AC200V~240V, 50Hz; ambient temperature: 5~40ºC; relative humidity: ≤85%(30ºC)

Overall power consumption: ≤30W

Dimensions and weight: 468mm * 368mm * 136mm, 13.8Kg