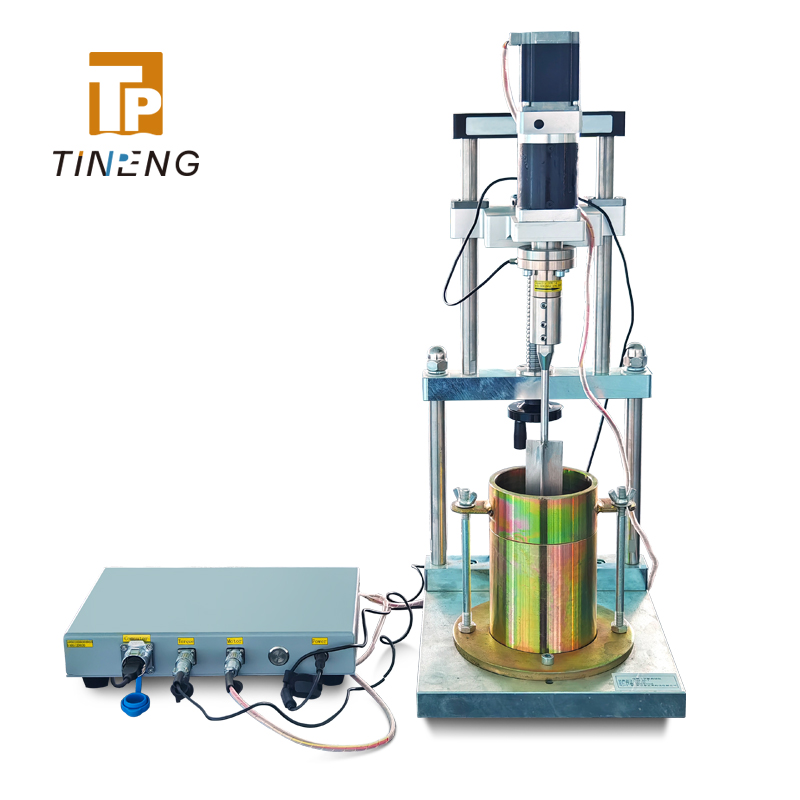

AUTOMATIC VANE SHEAR TESTER TPAS-1

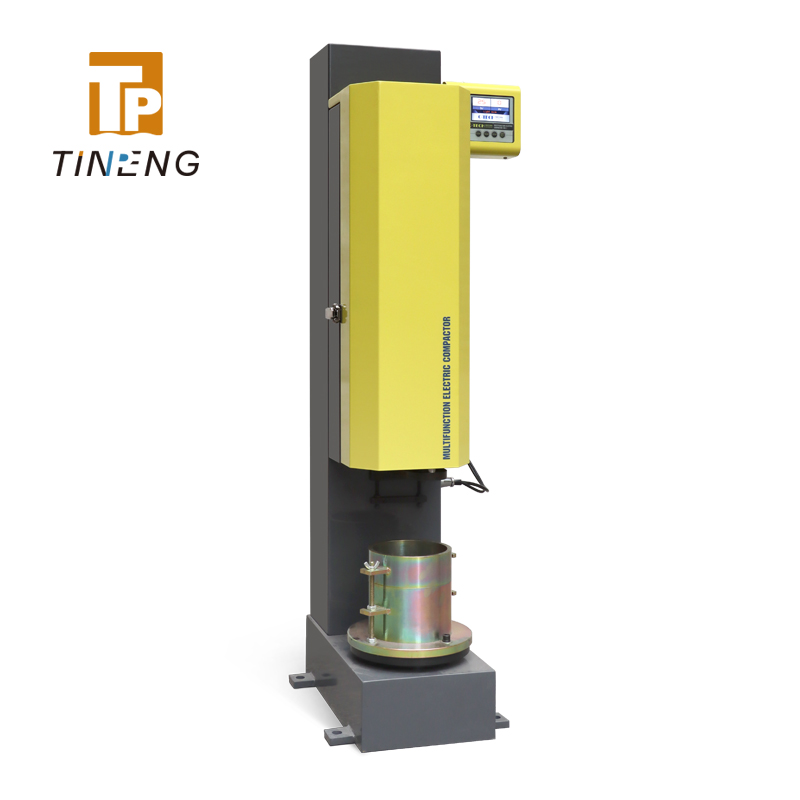

The automatic vane shear tester TPAS-1 is a laboratory geotechnical testing equipment used to determine the shear strength of soft soil or sensitive clay. It not only can determine the undrained strength of undisturbed soil taken at different depths, but also can perform tests under different consolidation pressures (this function is optional) and determine soil sensitivity.

STANDARD

- ASTM D4648

Get Wholesale Price

The automatic vane shear tester TPAS-1 is a laboratory geotechnical testing equipment used to determine the shear strength of soft soil or sensitive clay. It not only can determine the undrained strength of undisturbed soil taken at different depths, but also can perform tests under different consolidation pressures (this function is optional) and determine soil sensitivity.

FEATURES

-It has overload protection function.

-Equipped with a high-speed USB 3.0 communication port for communica-tion with computers, which is widely applicable, fast in transmission, and stable and reliable in communication.

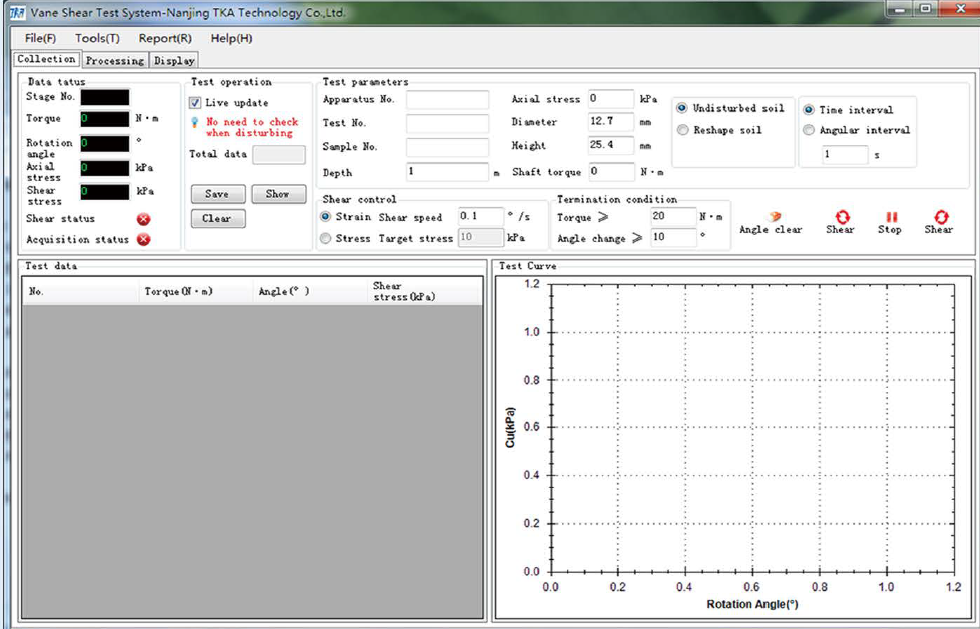

-Data acquisition: by time interval (s) or by shear interval (°).

-Supports the latest Win10/11 operating system.

TECHNICAL SPECIFICATIONS

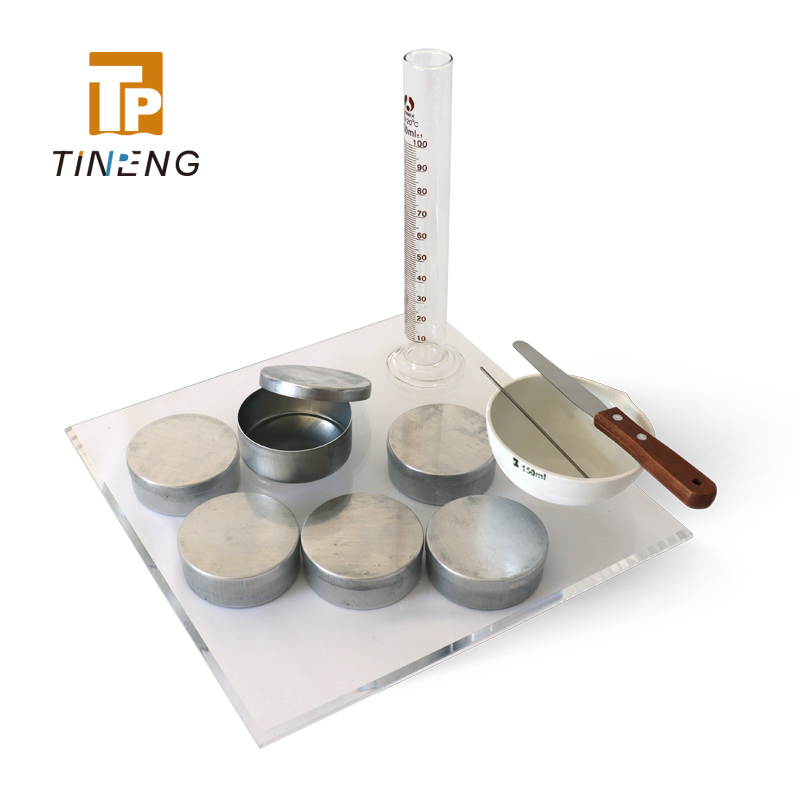

Vane | Made of 304 stainless steel, using integral wire cutting technology, with a thickness of not less than 2mm. Φ12.7mm×h25.4mm Φ25.4mm×h50.8mm Φ38.1mm×h76.2mm Other specifications can be customized | |||

| Specimen container | Φ100mm×h177mm | |||

| Shear rod | The maximum depth is not less than 220mm. Other sizes are optional, such as 1000mm for vacuum preloading. | |||

| Torque sensor | 0-5, 0-10, 0-20, 0-50, and 0-80 N.M selectable. Accuracy: +/-0.1% F.S Resolution: ≤0.1 N·m; | |||

| Shear rate | 0.001~200°/min, continuously variable speed. | |||

SOFTWAR

The software includes a consolidation module (optional) and can plot shear strength versus vertical load curves (optional), facilitating future instrument upgrades and expansions. It features

fully automatic data acquisition and control, with the following functional modules: data acquisition module, data processing module, sensor calibration module, and report output modul.

CONFIGURATION

| Control box | Power switch, built-in data acquisition device, power socket, USB 3.0 port. |

| Container | Base plate, cylinder. Color galvanized, 304 stainless steel container optional. |

| Torque drive device | Frame, lifting parts, stepping motor, coupling, vane |

| Torque sensor | Measuring range is optional. |

| Acquisition controller | |

| Acquisition and processing software | |

| Other supporting accessories |