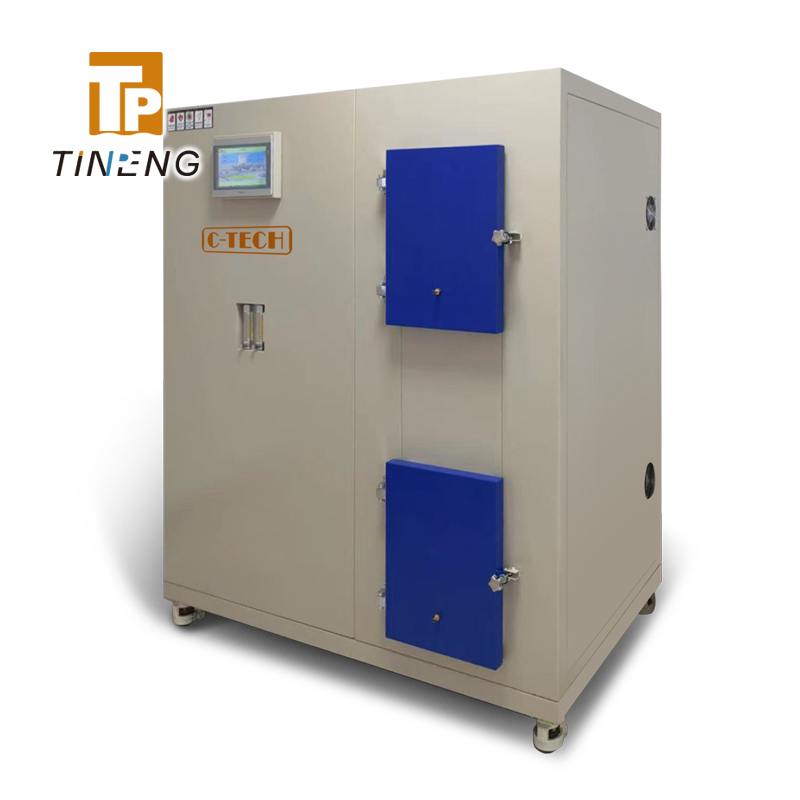

VOC emission chamber TPV-60

This equipment is used to test the emission of harmful substances such as volatile organic compounds, total volatile organic compounds (TVOC), benzene, toluene, the sum of xylene and ethylbenzene, carbon disulfide and formaldehyde. It is mainly suitable for plastic runways, coatings, adhesives, automotive interiors, furniture, artificial panels, floor coating materials, electronic and electrical products, interior decoration materials, etc.

STANDARD

- ASTM D 5116-06

- ASTM D 6670-01

Get Wholesale Price

This equipment is used to test the emission of harmful substances such as volatile organic compounds, total volatile organic compounds (TVOC), benzene, toluene, the sum of xylene and ethylbenzene, carbon disulfide and formaldehyde. It is mainly suitable for plastic runways, coatings, adhesives, automotive interiors, furniture, artificial panels, floor coating materials, electronic and electrical products, interior decoration materials, etc.

This equipment is equipped with two standard test chambers, which can test multiple samples at the same time, providing high work efficiency.

WORKING PRINCIPLE

Place the sample in a test chamber with specified temperature, humidity and ventilation conditions. After a certain period of time, the emission of harmful substances released by the sample is determined by detecting the concentration of harmful substances in the chamber air.

FEATURES

· The interior is a mirror stainless steel test chamber, with a smooth surface that does not condensate or adsorb, ensuring detection accuracy; the outer layer made of hard foam material, and the door is made of silicone rubber sealing strips, which have good thermal insulation and sealing properties. It not only reduces energy consumption but also reduces the balancing time of the equipment.

· The door of the chamber is made of silicone rubber sealing strips, which have good thermal insulation and sealing properties. The box is equipped with a forced air circulation device (to form a circulating air flow) to ensure a uniform temperature and humidity inside the chamber.

· Clean the constant temperature and humidity air supply system, an integrated device for high clean air treatment and humidity adjustment.

· The equipment is equipped with full protection devices and system safe operation protection devices, making the equipment operation more reliable and safer.

· The heat exchanger technology is advanced. The heat transfer efficiency is high and the temperature gradient is small.

· The temperature control of the temperature regulating water tank is stable. The water tank has high and low temperature alarms and high and low water level alarms.

· The temperature and humidity sensor has high accuracy and stable performance.

· Imported refrigerator, stable operation and long service life.

· The compressor also has overheating, overcurrent, and overpressure protection measures, making the entire equipment safe and reliable in operation.

· The equipment adopts advanced jacketed structure, which is compact, clean, efficient and energy-saving.

TECHNICAL PARAMETERS

Test chamber

Number: 2

Size: 400×500×300mm

Volume: 60L, the volume error is not more than 2%

Made of mirror stainless steel (8k mirror), The inner wall adopts rounded corners to eliminate dead corners for air circulation (can be customized).

Door: Independent control, the adjustment stroke is not less than ±5mm. Use a well-sealed surface-mounted lever lock.

Application

The test cabin can conduct standard tests corresponding to test temperature 60±2℃, humidity 5±2% and pretreatment temperature 23±2℃, humidity 50±10%.

Working temperature

20~65℃, each chamber is equipped with an independent high-precision temperature sensor.

Working humidity

4~60%RH. It adopts imported high-precision sensors and adopts dry gas and wet gas proportional control method. The humidification device is equipped with an automatic constant temperature control device;

The time to reach the set humidity is no more than one hour. After stabilization, the humidity fluctuation range is no more than ±2% RH.

Humidity uniformity: ≤±2% RH.

Humidity resolution: 0.1% RH

Plastic runway test temperature

Temperature range: (60±2)℃

Control accuracy: ±0.5℃

Measurement accuracy: ±0.1℃

Plastic runway test humidity

Humidity range: (5±2)%R.H

Control accuracy: ±3% R.H

Measurement accuracy: ±1% R.H

Adjustable range of air exchange rate

0.1~2 times/hour, the air source and purification system are integrated internally, and there is no external air source. Meet the ventilation requirements for plastic surface testing (1 time/hour)

Background concentration

Formaldehyde: ≤0.006mg/m3

Monomeric VOC: ≤0.002mg/m3,

TVOC: ≤0.02mg/m3;

Air supply purification system

Adopt multi-stage purification. Including high-temperature catalytic oxidation VOC purification components, low-temperature cooling VOC purification components, cold dryer water and oil removal purification components, dust particle filter purification system, formaldehyde filter, high-efficiency laminated activated carbon adsorption filtration system and other multiple purification methods.

Average recovery rate of pollutants in the chamber

≥80% (toluene or n-dodecane)

Number of sampling ports

2 per chamber, equipped with sampling adapters.

Noise

No more than 65 decibels (1 meter away from the device)

When the equipment is running, the pressure inside the test chamber relative to the outside

(10±5) Pa

Working conditions

Temperature: 20~25℃;

Atmospheric pressure: 86~106kPa

There is no strong vibration around;

There is no strong magnetic field around;

No high concentration of dust or corrosive substances around

Power supply

220V 50Hz, current is not less than 16A