HY-AMPT-30

HY-AMPT-30 asphalt mixture performance tester adopts hydraulic loading method, realizes the waveform output of loading force by con-trolling the hydraulic servo valve. At the same time, high-precision displacement sensors are used to accurately measure the deformation of the specimen during the test, so as to accurately evaluate the strength, dynamic modulus, fatigue and other properties of the pavement material, and simulate the various mechanical effects that the pavement material is subjected to during actual use.

HY-AMPT-30 asphalt mixture performance tester adopts hydraulic loading method, realizes the waveform output of loading force by con-trolling the hydraulic servo valve. At the same time, high-precision displacement sensors are used to accurately measure the deformation of the specimen during the test, so as to accurately evaluate the strength, dynamic modulus, fatigue and other properties of the pavement material, and simulate the various mechanical effects that the pavement material is subjected to during actual use.

FEATURES

HOST

◎ Built-in dynamic load hydraulic cylinder + high-frequency solenoid valve to generate various pressure waves (sine wave, sine wave, triangle wave, trapezoidal wave, etc.) required for the test.

◎ The main displacement sensor is installed inside the hydraulic cylinder to save space.

◎ The pressure sensor is installed on the top of the piston rod to avoid the generation of pressure components.

◎ The triaxial column reaction frame has higher structural stability.

ENVIRONMENTAL CHAMBER

◎ Use double-cavity vacuum composite glass to achieve efficient heat insulation while improving test visibility.

◎ Adopts pneumatic lifting system, which can be lifted with one button, providing 360mm barrier-free operating space for test

◎ operations.The small space design has higher temperature control accura-

◎ cy and efficiency, while also reducing energy consumption.Confining pressure tests such as dynamic modulus and flow

◎ value times can be carried out directly without the need for confining pressure cylinder.Adopts advanced multi-hole directional airflow circulation system to make the temperature more uniform.

EXTERNAL CIRCULATION

TEMPERATURE CONTROL SYSTEM

◎ Independent temperature control system, based on the frequency conversion control principle to control the cooling or heating power.

◎ Uses a color LCD touch screen control to accurately adjust the compressor speed and the power of the heating device to achieve precise temperature control.

◎ The temperature control system and the host are connected with flexible materials to avoid the influence of the vibration of the temperature control system on the test results.

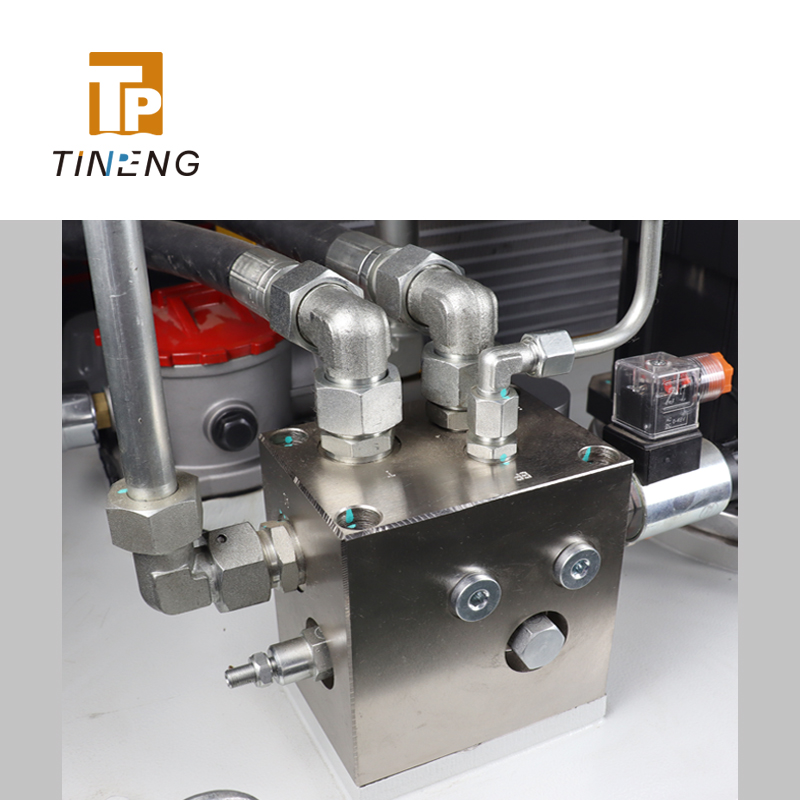

HYDRAULIC UNIT

◎ The silent design of the servo motor replacing the traditional three-phase motor effectively avoids the noise impact on other tests being conducted simultaneously.

◎ Install high-precision filters at the oil inlet and outlet to extend the service life of the hydraulic cylinder.

◎ Integrated valve block design simplifies the oil circuit.

TECHNICAL SPECIFICATIONS

Maximum loading capacity:30KN

Confining pressure range:0~300kPa

Pressure measurement accuracy:5N

Displacement measurement accuracy:+2.5μm

Frequency range:0.01~25Hz

Control method:Hydraulic loading

Environmental chamber dimensions:Inner diameter 320mm, inner height 395mm

Environmental chamber temperature:-10-60℃

Temperature control method:External circulating air

Triaxial cell dimensions:Ø340mm×395mm

Noise level:<60dB (within 2m)

Operating system:Windows 11

Power supply :380V 50Hz

Host dimensions:700×700×1400mm