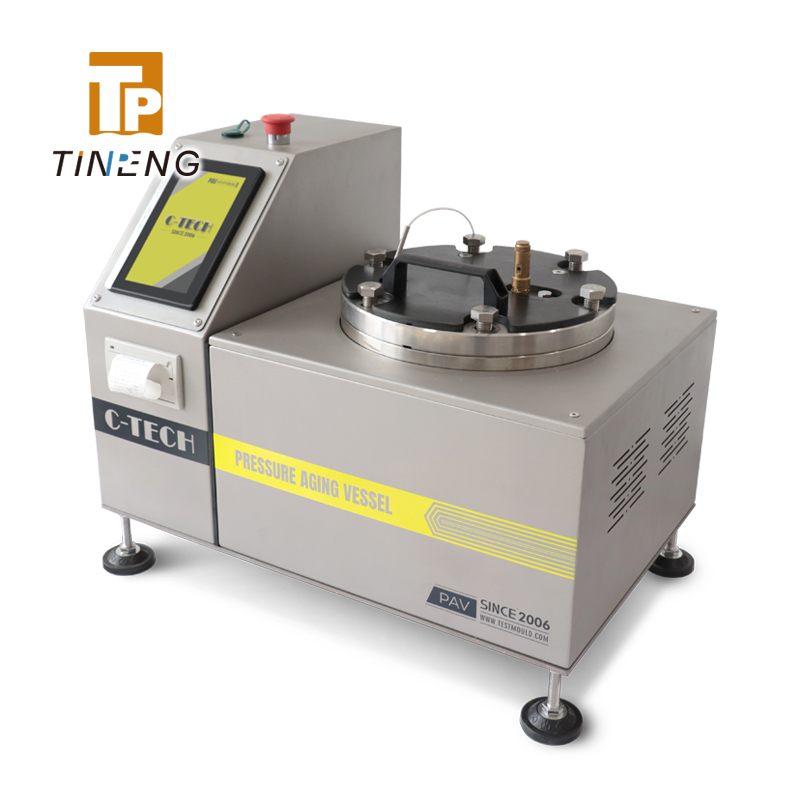

HTHY-0630 PAV

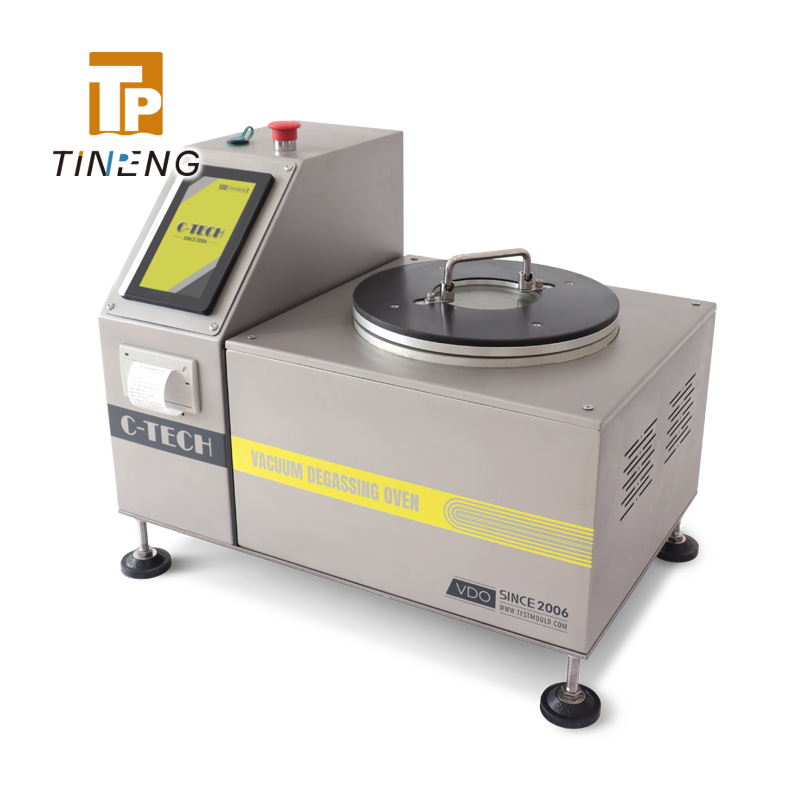

PAV Asphalt Pressure Aging Vessel HTHY-0630 is used to simulate the long-term aging process of asphalt under the action of climate and traffic load, to evaluate the anti-oxidative aging ability of different asphalt under certain test temperature and pressure conditions, and to provide aging asphalt samples for performance tests.

STANDARD

- ASTM D6521

- AASHTO R-28

- EN 14769

Get Wholesale Price

PAV Asphalt Pressure Aging Vessel HTHY-0630 is used to simulate the long-term aging process of asphalt under the action of climate and traffic load, to evaluate the anti-oxidative aging ability of different asphalt under certain test temperature and pressure conditions, and to provide aging asphalt samples for performance tests.

The lightweight structure of the equipment fits perfectly on any standard laboratory benchtop and is easy to operate and maintain.

FEATURES

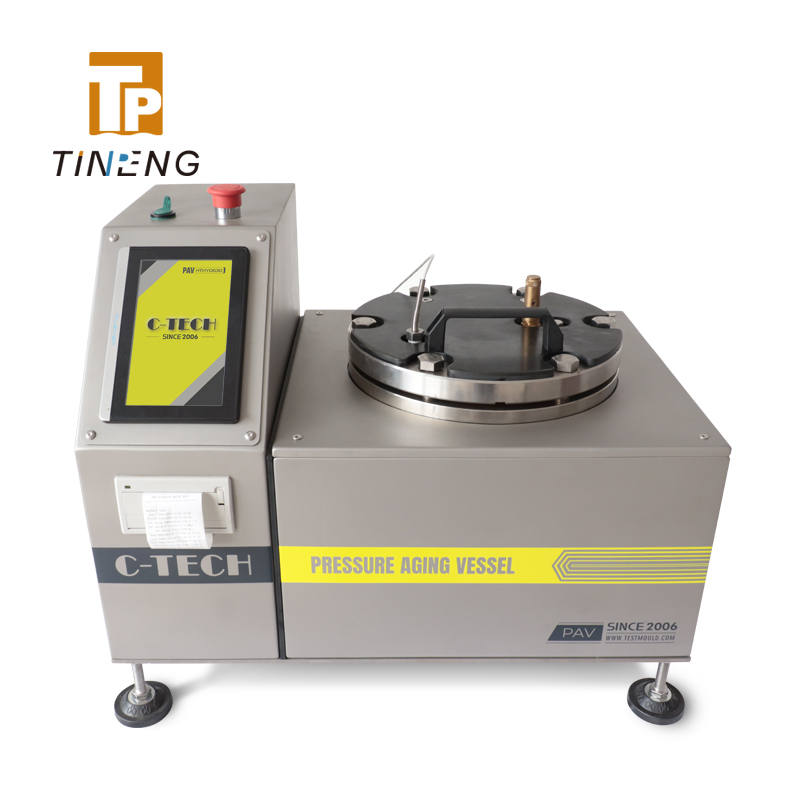

· 7-inch high-definition display controller, real-time monitoring of pressure and temperature in the chamber;

· Display the temperature-time and pressure-time curves in the chamber during the working process;

· Real-time display of the temperature error time and pressure error time of the aging process (to meet the requirements of the new specification);

· Temperature and pressure linkage control to ensure no overheating during pressurization;

· Record the data once every 5s, and export it as excel format data via U disk;

· After the test is completed, the process data can be automatically printed;

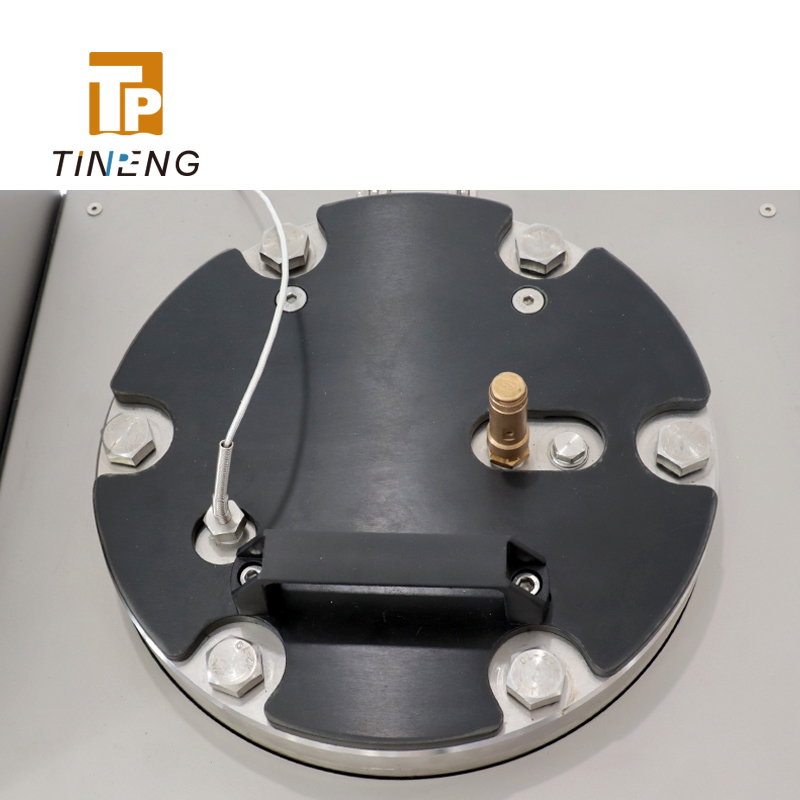

· Safety protection designs such as over-temperature, over-pressure protection, and high-pressure relief can effectively protect experimenters working under high-temperature and high-pressure experimental conditions;

· With overload protection, fault warning and other functions, there is a buzzer sound alarm prompt and display the fault code at the same time;

· The cabinet is made of stainless steel, treated with special technology, easy to clean and durable.

TECHNICAL PARAMETERS

Working temperature range: 90~110℃

Temperature control accuracy: Resolution 0.1℃, accuracy ±0.5℃

Preheating time: 40min~60min

Temperature-pressure: Real-time display temperature and pressure values and curve relationship

Working pressure: 2.1MPa±0.1MPa

Actual pressure control accuracy: ±0.02MPa

Pressure sensor: 0-3MPa

Accuracy: 0.5% (±0.015 MPa)

Air supply: Cylinder compressed air, air pressure greater than 3MPa

Air supply connector: Equipped with high-pressure pressure reducing valve and converted high-pressure air pipe matching with industrial compressed air bottles as standard

Safety relief: Greater than 2.5Mpa

Safety valve: When the pressure in the chamber exceeds 2.5Mpa, the safety valve automatically releases pressure

Power supply: AC220V 50Hz

Dimensions: 550X350X450 mm

Weight: 60kg

· 1 high-pressure pressure reducing valve, 1 high-pressure resistant air inlet pipe (3m), used to connect the equipment to the compressed air cylinder, and adjust the inlet pressure of the air source

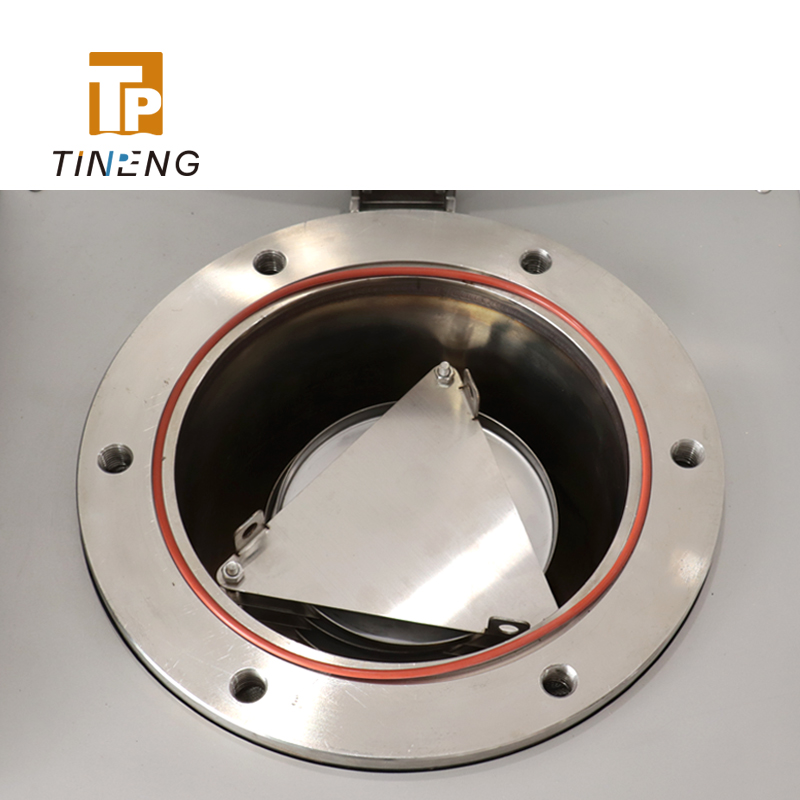

· Sample dishes (10 pcs) and rack