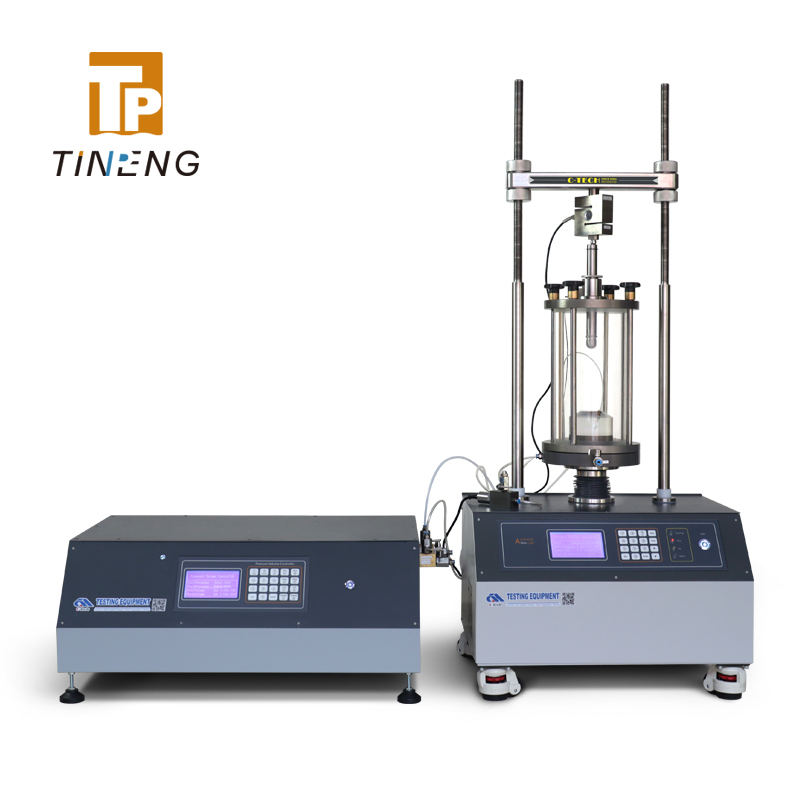

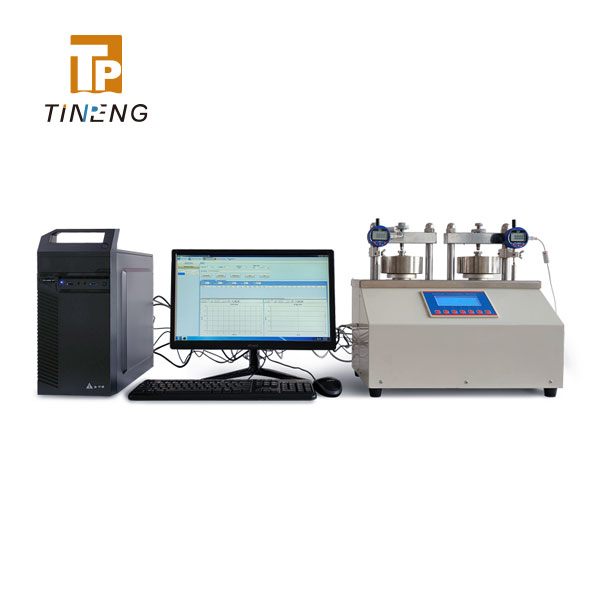

TSZ-1T

The semi-automatic triaxial testing system is adopting the most advanced technology. It is integrated the technology of mechanic, electronic, fully-automated control and sensor automated checking.

STANDARD

- ASTM D4767

- ASTM D2850

- ASTM D2166/D2166M

Get Wholesale Price

The semi-automatic triaxial testing system is adopting the most advanced technology. It is integrated the technology of mechanic, electronic, fully-automated control and sensor automated checking.

The device consists of Triaxial Loading Frame, Advanced Pressure Volume Controller (APVC), Triaxial Cell, various sensors, temperature control devices and AdvancedGeoLAB® software. The range of Triaxial Loading Frame has been designed to be used as part of computer controlled triaxial system or as a stand alone unit. The Triaxial Loading Frame and Advanced Pressure Volume Controller both are equipped with the LCD graphical display and panel keypad.

TEST-CONTROL MODULES

◎ Data Acquisition Module;

◎ Back Pressure Saturation Test;

◎ Consolidation in same direction and consolidation in different direction (pre contact) test;

◎ Unconsolidated – undrained test (U-U test);

◎ Consolidation – undrained test (C-U test);

◎ Consolidation – drainage test (C-D test);

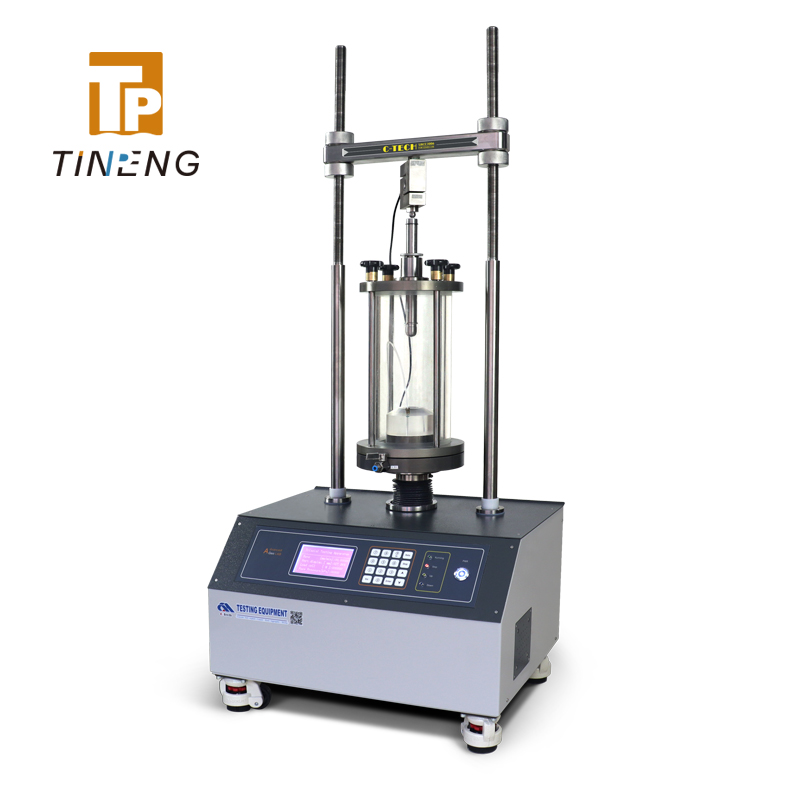

TRIAXIAL LOAD FRAME

Triaxial Loading Frame has good rigidity, durability, low noise and smooth operation, adopts the stepper motor coupled with worn gear drive system to supply the power source. It is equipped with upper and lower limit device; the axial deformation is measured and collected by high-precision displacement sensor. Axial load is measure by force sensors. With overload protection device, when the axial force loaded is larger than the measuring range of the sensor, the machine will stops working automatically.

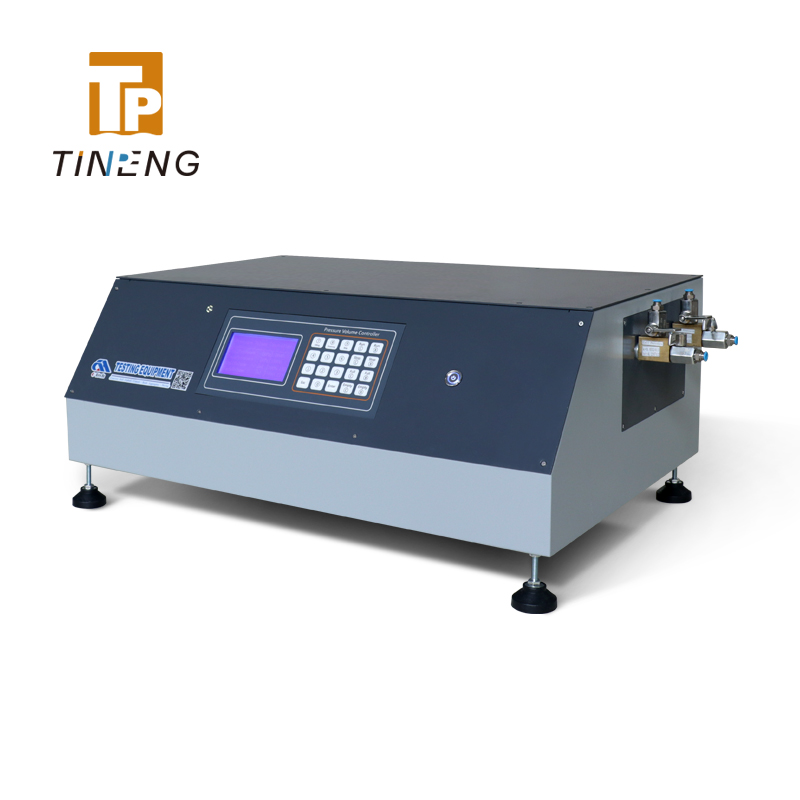

ADVANCE PRESSURE VOLUME CONTROLLER

The Advanced Pressure Volume Controllers is very easy to use and an ideal solution for the most modern laboratories. When used with Triaxial Loading Frame, data loggers and software, they can be controlled from a computer to form part of a complete automated triaxial testing system. They may also be used as stand alone units which are fully functioning with or without computer control. All the devices have their own computer interface. The devices come complete with internal volume and pressure transducers. Both channels are pre-calibrated, it can generate pressures up to 2MPa and provides a maximum volume measurement of 60ml which is readable to 0.001ml.

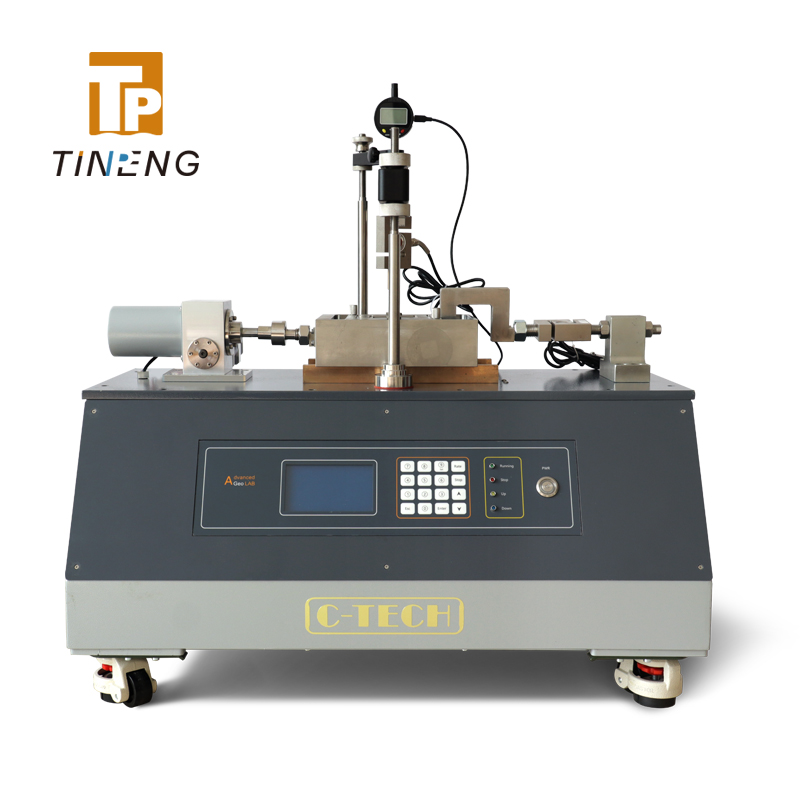

TRIAXIAL CELL

It is mainly composed of base, middle ring, upper cover, side wall and loading rod, etc. It is connected by quick clamp rod, which is easy to disassemble. There are 3 drainage ports at the bottom for connecting hole pressure, confining pressure and back pressure.

TECHNICAL PARAMETERS

TRIAXIAL LOAD FRAME TSZ-1T

Maximum Axial Force (Load Sensor): 10 kN

Testing Speed Rate: 0.00001 - 9.99999 mm/min

Precision: +/- 0.1% F.S.

Displacement Sensor Measuring Range: 25mm with accuracy 0.01mm

Maximum Vertical Clearance: 500mm

Horizontal Clearance: 260mm

Platen Diameter: 96mm

Power: 110-240V, 50Hz

Dimension(mm): 480 x 445 x1190mm

Weight(kg): 45

ADVANCE PRESSURE VOLUME CONTROLLER TPS-PVC-1

Channel: 2 Channel

Maximum Pressure: 2MPa

Resolution: 1kPa

Maximum Volume: 60ml

Resolution: 0.001 ml

Precision: +/- 0.1 % F.S.

Confining Pressure: Measuring Range: 0 ~ 2 MPa, Resolution: 1 kPa, Accuracy: +/- 1 kPa

Back Pressure: Measuring Range: 0 ~ 2 MPa, Resolution: 1 kPa, Accuracy: +/- 1 kPa

Power supply: 110V or 240V,50Hz

Dimensions: 870×530×320 (mm)

Weight: 38Kg

TRIAXIAL CELL TPS-YLS50

Sample Size: 50/38mm

Maximum Cell Pressure: 2000 kPa

Dimensions: Ø 180 mm

Weight: 12kg

TRAINING

Training services are available for this equipement, including on-site training, training videos and training documents. Contact us for a quote.

Duration: 2 days

|

|

|

| On-site training | Training videos | Training documents |