HYRS-6

The asphalt content ignition oven HYRS-6 is a micro controller based equipment based on the electric ignition oven method for fast and accurate determination of asphalt content.

The Asphalt Ignition Oven is a cost effective and environmentally friendly method for the determination of asphalt content using electric ignition method. The asphalt content ignition oven HYRS-6 has an internal electronic balance that automatically monitors the sample weight throughout the ignition process, saving valuable time and increasing productivity.

The asphalt content ignition oven HYRS-6 is a micro controller based equipment based on the electric ignition oven method for fast and accurate determination of asphalt content.

The Asphalt Ignition Oven is a cost effective and environmentally friendly method for the determination of asphalt content using electric ignition method. The asphalt content ignition oven HYRS-6 has an internal electronic balance that automatically monitors the sample weight throughout the ignition process, saving valuable time and increasing productivity.

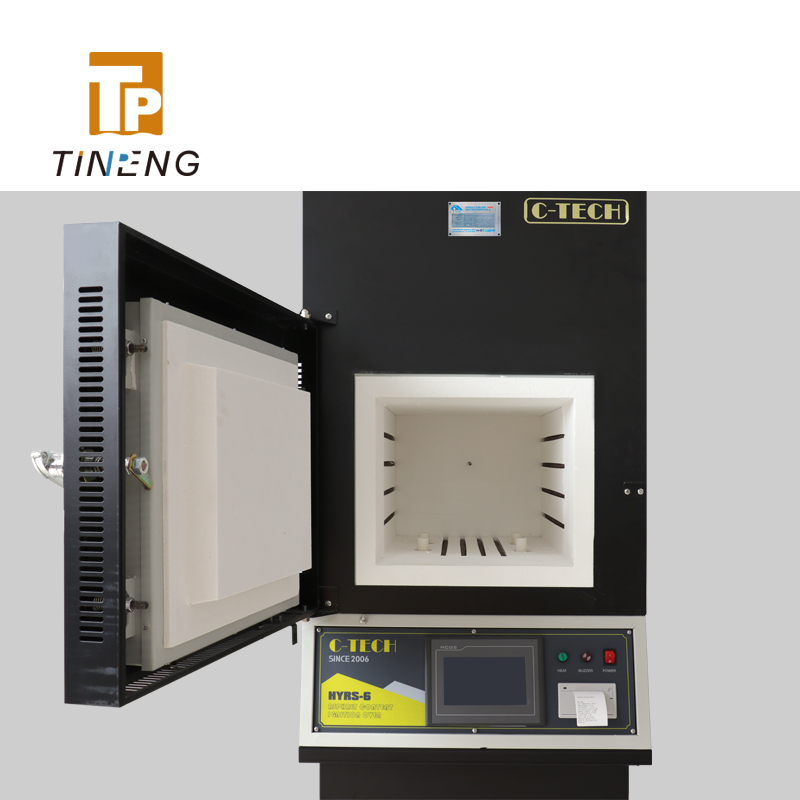

The equipment comprises three parts: combustion device electric furnace, a sophisticated electronic balance for weight measurement integrated with a test control and data processing micro controller unit.

All of the data is display in real time on the touch screen controller. Above the furnace chamber is a fumes assembly chamber where the fumes mix with air before being exhausted through the flue by the fan.

FEATURES

·Using the microcontroller unit and high-precision electronic balance, it is simple and easy not only to use but to maintain.

·Accurate endpoint detection according the pre-set calibration factor.

·Using new type furnace structure, heating up fast, short test time.

·New and beautiful appearance design. Furnace and balance accurate positioning for ensuring the sample center is located in the middle of balance.

·To every type of need-to-test asphalt mixture, with reference to standard technical require of American

·ASTM D6307-98 and AASHTO T308-99, use calibration sample to determine calibration system of asphalt mix to ensure credibility of the test result.

TECHNICAL PARAMETERS

Electrical ratings: 380V(±10V); amps ≤20A

Capacity of balance: 10kg, division value:0.1g

Operating temperature of Chamber: up to 800℃

Sample capacity: up to 4000g

Recommended weight of sample: 1000~1500g

Chamber Dimensions: 350x440x330 mm( WxDxH)

Test accuracy of asphalt content: 0.1%

Microcontroller Unit: The control panel is installed in front of the equipment. Operator can set the test parameter by pressing the buttons and progress the test. While testing, the monitor displays the real-time test data and parameter. Automatically the result paper which will be printed out by the printer is generated by the system after the test.

Overall size: 1080X820X1850 mm

Weight: 260kg