TPPZ

Rail straightness directly influences the running speed of the train and the comfort of passengers, even the running safety. Portable Laser Straightness Gauge is a user-friendly and simple to use instrument designed to measure without contact the rail geometry.

Get Wholesale PriceRail straightness directly influences the running speed of the train and the comfort of passengers, even the running safety. Portable Laser Straightness Gauge is a user-friendly and simple to use instrument designed to measure without contact the rail geometry.

APPLICATION

Detecting short-wave irregularities

Detecting the quality of rail welded joints

Guide the repair of welded joints according to the waveform diagram

MEASUREMENT PRINCIPLE

Rail top surface measurement adopts laser sensor to measure the middle line of rail top with sampling interval of 1mm.

The principle of rail side measurement is similar to that of rail top surface measurement. The difference is that the rail top surface measurement is carried out in the vertical plane, while the rail side measurement is carried out in the horizontal plane. The measurement point is 16mm below the rail top surface.

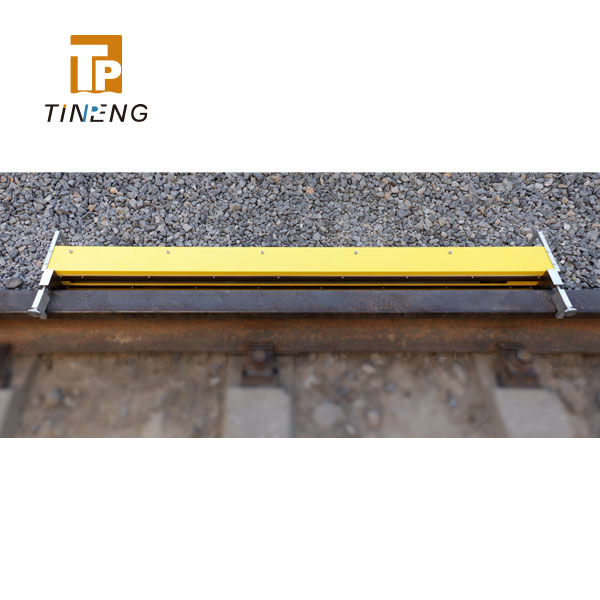

ASSEMBLY

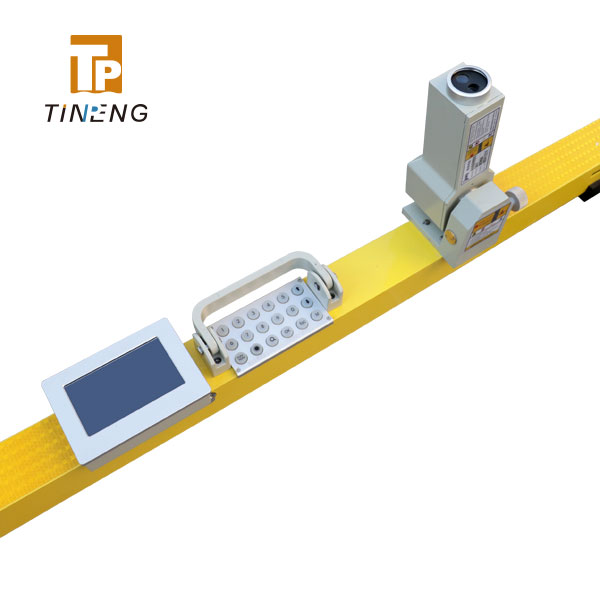

Rail straightness measuring instrument is mainly composed of two parts: frame and PDA. The laser sensor, signal processing interface board, power supply module and other integrated devices are installed on the rack. The rack and the PDA are connected by wireless communication.

FRAME

The frame is fixed on the top.

SENSOR

Laser displacement sensor with high accuracy to measure the short-wave irregularity on the top and inner working side of the rail.

SIGNAL PROCESSING INTERFACE BOARD

The weak signal of the sensor is amplified and filtered for digital conversion, and provides an interface to the computer.

POWER MODULE

Provide long-term and stable power for laser sensor and signal processing interface board.

DIAGNOSTOR

It processes and stores digital signals, dispalys measurement data in real time.

MAIN FEATURES

The precision guide rail is adopted as the measurement baseline, which can accurately reflect the real value and eliminate the principle defects in the original measurement method of steel plate ruler and feeler gauge. At the same time, many new technologies are applied, such as using high-precision laser displacement sensor to measure the chord height, and using special collector or laptop to collect and process data.

TECHNICAL PARAMETERS

Ambient temperature: -30 ~ +50 °C

Rail temperature: -20~ +60 °C

Related humidity: ≤90%RH

Protection class: IP54

Rails which can be measured: UIC54, UIC 60…

Measuring basic length: 1.0 m ( customizable)

Horizontal resolution: 1000 measuring points

Vertical resolution: 0.01 mm

Measuring accuracy: 0.02mm

Measuring range: -2~ +1mm

Measuring time: 7s

Measuring principle: Laser measurement photoelectric image principle

Laser wavelength: 650nm

Memory capacity: 10000 welding profiles

Electric current: 3500 mAh

Charging time: approx. 10 hrs

Connection interfaces: USB or Bluetooth

Battery power: > 1000 times measurement

Standard requirements: EN 61000-4-2 EN 55022

Weight: 5kg

Dimensions (W×D×H): 1230 × 165 × 110 mm