HTHY PSRT-2

This laboratory instrument applies the Wehner/Schulze method to accurately measure post-polish friction on asphalt, concrete, and other material samples.It accommodates samples of various sizes to realistically simulate tire-road skid resistance behavior. The system’ s testing technology has been aligned with international industry standards while maintaining the original measurement principle.

STANDARD

- EN 12697-49

Get Wholesale Price

This laboratory instrument applies the Wehner/Schulze method to accurately measure post-polish friction on asphalt, concrete, and other material samples.It accommodates samples of various sizes to realistically simulate tire-road skid resistance behavior. The system's testing technology has been aligned with international industry standards while maintaining the original measurement principle.

FEATURES

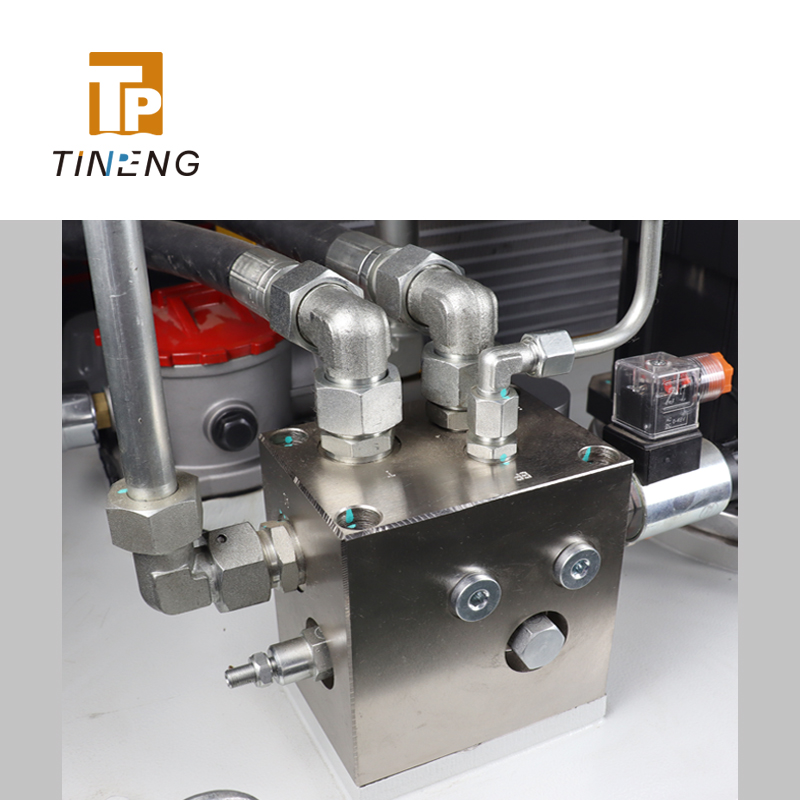

-The use of stainless steel provides excellent corrosion resistance and extends the service life of the equipment.

-The test chamber is equipped with an acrylic protective cover to prevent water splashing while allowing clear observation of the experimental process.

-The four-station design facilitates convenient operation and improves efficiency.

-An independent calibration station avoids operational errors caused by repeated installation of standard reference plates.

-An upgraded mixer and water pump are used for mixing and pumping abrasive materials, enhancing experimental efficiency.

-The main skid resistance measurement platform incorporates a high-precision torque measurement system and a fully automated testing program, enabling more convenient and accurate wear and skid resistance performance testing.

-A new corrosion-resistant temperature control system ensures precise and reliable temperature management during experiments.

-The equipment supports programmable test processes, including polishing, cleaning, and measurement, improving experimental flexibility and accuracy.

-It is equipped with a high-quality industrial controller with a touchscreen and graphical display, allowing simultaneous monitoring of measured values and the testing process,while providing multiple control modes and functions with graphical output.

SPECIFICATION

Polishing wheel:D1=Φ36 ± 1mm, D2L: Φ80 ± 1mm,Height: (57.5±0.5)

Polishing ring width:Φ115mm-230Φmm,±1mm

Polishing gyratory speed (RPM):0rmp~600rmp

Polishing Head Pressure (kPa or N):392N±3N

Specimen Dimensions (e.g., Length × Width × Height in mm):300mm×300mm×(40~100)mm

Quartz Powder Mixture Flow Rate (L/min):5L±0.5/min

Quartz Powder Mixture Temperature (°C):15°C±1°C

Specimen Clamp Dimensions (mm):300mm×300mm×50mm