ZHM series

For efficient dry or wet grinding of brittle and very hard samples to analytical fineness. Most suitable for "XRF" "XRD" and "AA" sample preparation.

For efficient dry or wet grinding of brittle and very hard samples to analytical fineness. Most suitable for "XRF" "XRD" and "AA" sample preparation.

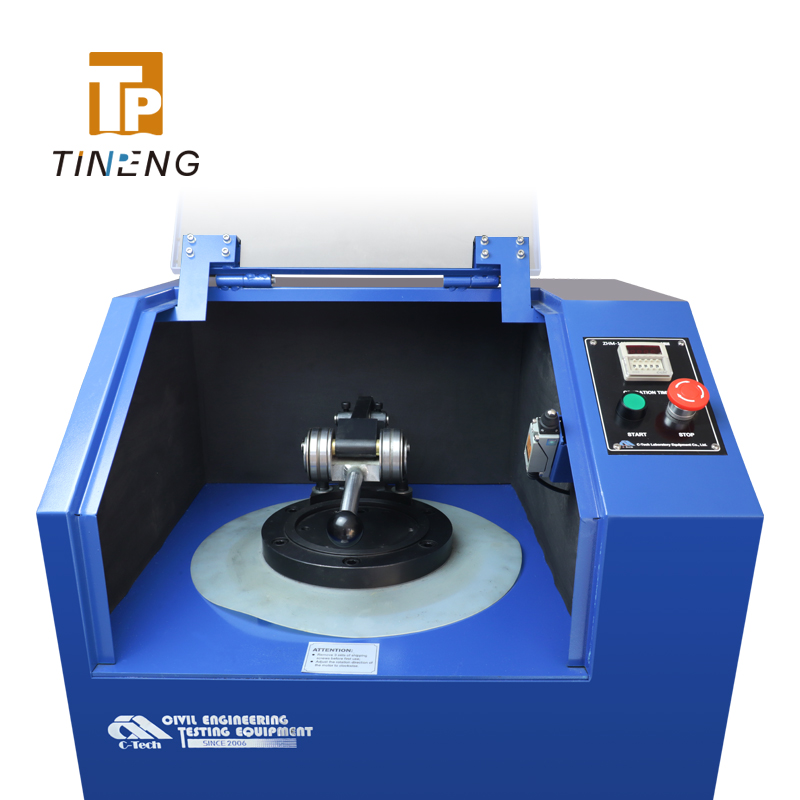

PRINCIPLE OF OPERATION

Grinding is done by heavy impact and friction. Sample is kept in the annular space between the bowl, ring and the puck. A cover is kept on the top of the bowl then the bowl is clamped on vibratory platform and subjected to heavy vibrations. The vibratory platform imparts the kinetic energy to the ring and the puck.

FEATURES

• Extremely fast grinding by impact and rubbing of trapped material under the grinding ring and puck.

• Analytically pure grinding without any loss of material.

• Reproducible grinding.

• Dry as well as wet grinding is possible.

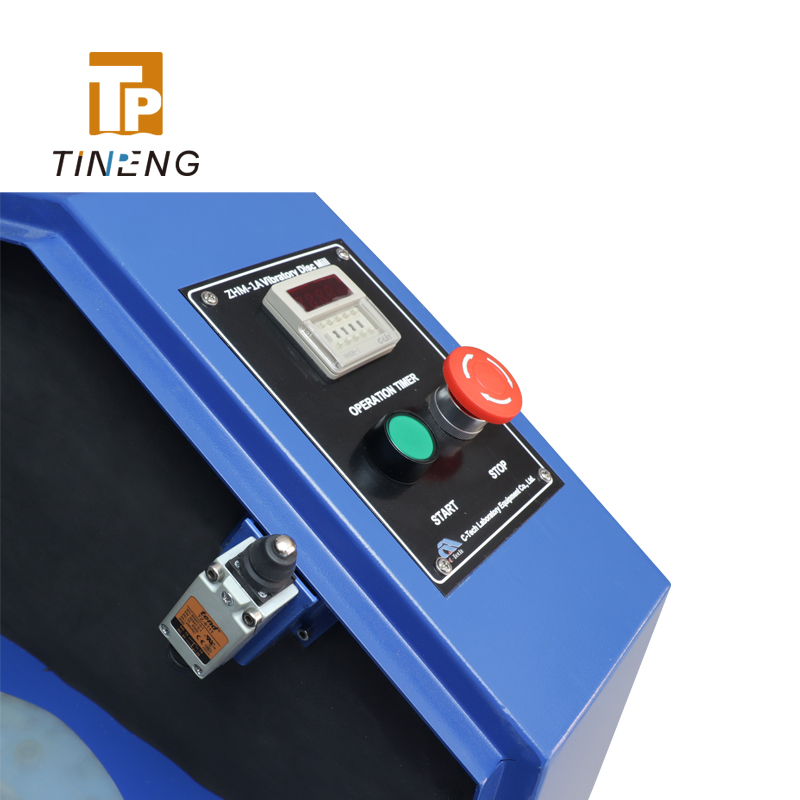

• Start & Stop Push button, Motor overload protection with door safety system and fault indication lamps are provided.

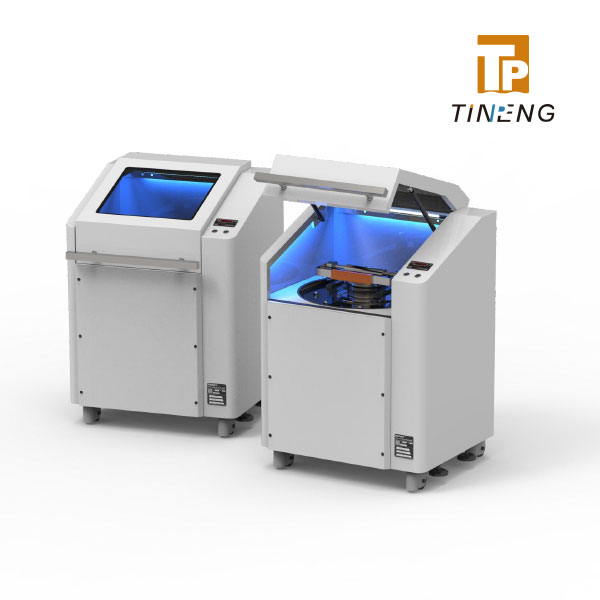

• Soundproof enclosure facilitates noise below 71db during operation.

• One year warrantee against any manufacturing defects.

MODELS

• REGULAR ZHM-1A Single bowl set with fixed speed 1400 r/min.

• ZHM-1B Single bowl set with fi xed speed 960 r/min.

• ZHM-1T Single bowl set with two speed 910/1400 r/min.

• ZHM-1V Single bowl set with adjustable speed from 750 to 1550 r/min .

• ZHM-3B Three bowl sets with fi xed speed 960 r/min.

TECHNICAL PARAMETERS

Application: For very fast grinding of medium, hard and very hard material, sample grinding for "XRF" "XRD" and "AA".

Useful capacity: 100ml (user to specify)

Maximum Feed size: 5mm

Time required For grinding: 1 to 3 minutes (depending on the material characteristics)

Output size: Upto 75 microns (depending on material properties).

Grinding elements: 1 bowl+1 ring + 1 puck for 100 ml

Material of grinding element: Hardened steel with tough core / AISI304-SS / Lined tungsten carbide / Tungsten carbide lined with Ti Al N coating / Agate / Zirconia (Stabilised) / Toughened Alumina / Corundum (natural and sintered).

Timer: 0-255 (minutes & seconds)

Power: AC380V10%, 50HZ, 3-phase+ Earth

Weight and Dimension: Machine: 180kg, 650x600x960mm Packed: 240kg, 820x760x1320mm(Ply wooden case) ZHM-3B Machine: 260kg, 710x810x1080mm Packed: 340kg, 780x880x1150mm(Ply wooden case)

Model CT01 Hardened alloy steel bowl set

Hardness: RC 60/62

Approximate Composition: Carbon 0.95%

Manganese 1.25% Chrome: 0.50% Tungsten 0.50%Vanadium 0.2%

Model CT02 Chromel steel bowl set

Hardness: RC 60/62

Approximate Composition: Carbon 2.0%

Chrome: 12.0% Molybdenum 085% Vanadium 0.2%

Model CT03 Lined tungsten carbide bowl set

Hardness: Approx 8.5 Mohs

Approximate Composition: Tungsten Carbide 94% Cobalt 5.5%

Trace elements in order of 0.002% to 0.02%: Iron, Nickel,

Vanadium, Tantalum & Silicon

These bowl sets need to be ordered seperately.